Piab USA Announces New Office Location in Canton, MA

The new office, located at 100 Energy Drive], will serve as the central hub for Piab USA's operations, housing its management, sales, support, R&D and distribution center.

Piab USA, a leader in industrial automation solutions, is excited to announce the relocation of its headquarters to a new, state-of-the-art office facility in Canton, Massachusetts. This move is part of Piab's strategic initiative to accommodate rapid growth and expand its capabilities in providing innovative automation technologies.

The new office, located at 100 Energy Drive, will serve as the central hub for Piab USA's operations, housing its management, sales, support, R&D and distribution center.

Enhanced Facilities for Innovation and Collaboration

The new Canton office is designed to foster innovation and collaboration among Piab's teams. Equipped with modern amenities, advanced technological tools, and spacious conference areas, the facility will enhance the company's ability to develop and deliver high-quality automation solutions. The office layout encourages open communication and teamwork, which are key to Piab's agile and responsive business approach.

A Word from the President of Piab USA

"We are thrilled about the move to our new office in Canton, which marks a significant milestone in our journey," said Ed McGovern, VP of Piab USA. "This new facility not only supports our growth ambitions but also reflects our commitment to providing our employees with a great working environment and our customers with exceptional service. We look forward to becoming an integral part of the Canton community and continuing to drive innovation in industrial automation."

About Piab

Piab is evolving automation through progressive gripping, lifting, and moving solutions. Since 1951, Piab has been serving industries like e-commerce logistics, food, pharma, automotive, and more, improving energy-efficiency, productivity, and work environments. With a presence in more than 100 countries, Piab is a global organization dedicated to developing automation solutions that enhance the efficiency and quality of production processes.

Featured Product

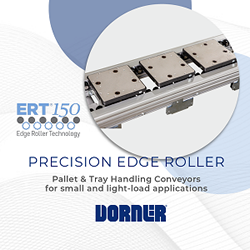

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.