Afinia 3D Wins RAPID 2015 Exhibitor Innovation Award for H800 3D Printer

The Afinia 3D H800 3D printer recently won the RAPID 2015 Exhibitor Innovation Award. The H800 was selected by the Society of Manufacturing Engineers (SME) Rapid Technologies & Additive Manufacturing (RTAM) Committee.

CHANHASSEN, Minn. May 29, 2015

Afinia 3Ds H800 3D Printer is gaining attention. The printer recently won the RAPID 2015 Exhibitor Innovation Award. The Afinia 3D H800 was selected by the Society of Manufacturing Engineers (SME) Rapid Technologies & Additive Manufacturing (RTAM) Committee.

"RAPID would like to congratulate Afinia 3D on winning the RAPID 2015 Exhibitor Innovation Award for their Afinia H800 3D Printer. The RAPID Exhibitor Innovation Award recognizes the most innovative new products or services exhibited at RAPID that are judged to have the greatest potential impact on the industry," said Maria Conrado, Event Manager.

John Westrum, Afinia 3D's Vice President, and Zack Sterzinger, Sales Representative, were happy to accept the award while exhibiting the Afinia 3D printers at the RAPID event. "We've listened to our customers and used their feedback to provide a printer that we feel will truly meet their needs," said Westrum. "The H800 has undergone months of testing and preparation to ensure that it meets the high standards that Afinia 3D sets for all of our products. We are looking forward to seeing what our customers will create with the bigger build area."

The Afinia H800 3D Printer has a build area 5x larger (10 x 8 x 8 inches) than the Afinia H480, and includes additional enhancements such as a HEPA filtration system, fully-automated leveling and height sensing, ultra-fine 100-micron print resolution, and one button filament changing. Although the H800 has many more features than the H480, the H800 still provides an "out-of-the-box 3D printing experience," arriving fully assembled with easy to install software for PC and Mac.

Pre-orders for the H800 begin shipping in June, with new orders shipping in July. To add your name to Afinia 3Ds waiting list for the H800, please visit their online store.

About Afinia

Afinia is a division of Microboards Technology LLC, a leader in specialized printing solutions. Their twenty-year history includes market-leading innovations in disc duplication, labeling and, most recently, 3D Printing. More information can be found on Facebook, Google+, or Twitter, or by phone at 1.888.215.3966.

About RAPID

For 25 years, the RAPID Conference & Exposition, produced by SME, has defined the crucial role of additive manufacturing and empowered the establishment of an industry that continues to conceive, test, improve, and manufacture new products at a faster, more cost-efficient pace. As the leader and authority figure in additive manufacturing, RAPID attracts buyers, sellers and end-users of design, prototyping, tooling and direct digital technologies to a world-class event for discovery, innovation and networking. For more information, please visit rapid3devent.com.

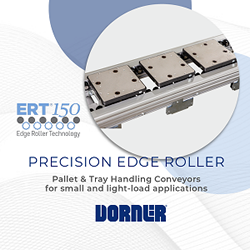

Featured Product

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.