Mr. Pedersen founded RE2, Inc. in July of 2001 to advance the state of the art in robotics technologies for the military. Since that time, Mr. Pedersen has grown the company to over 60 employees with work in all aspects of robotics from innovative research in actuation and control to manufacturing of highly complex 2-arm manipulation systems. Mr. Pedersen currently serves as the Vice Chair of the Robotics Division of National Defense Industry Association (NDIA) and sits on the NDIA Board of Trustees. He also sits on the Robotics Technology Consortium (RTC) Board of Directors and the OSD Joint Ground Robotics Enterprise Senior Steering Group.

Jorgen David Pedersen | RE2, Inc.

How do you foresee DoD successfully establishing an integrated manned/unmanned force on our frontline? How long do you think it will take to make that happen?

We are already seeing the integration of manned/unmanned forces, especially on the ground. Currently, ground robots are transported by manned vehicles and even by dismounted troops until those unmanned ground systems are needed for a mission. As a result, military techniques, tactics, and procedures are continuing to adapt to support this manned/unmanned environment.

There’s been talk of further investments being placed in new warfighter technologies, like robots. In a time of budget crunch, do you think this vision is attainable? Why? How?

Even in a downed economy with a waning Defense budget, I believe that the robotics industry will continue to grow. It comes down to return on investment. The investment needed to develop a robot that will save lives and/or improve effectivess/efficiency is typically far less than comparable programs within the DoD. Moreover, with the adoption of the open architecture paradigm for robotic systems, new technologies will be able to be inserted more rapidly and inexpensively, providing even greater return on investment.

The theme of the 2012 NDIA Ground Robotics Capabilities Conference is “"What Will it Take to Achieve the Vision?" Requirements, Technology, Acquisition, ROI” – how will NDIA answer that question over their 3-day Conference?

NDIA has gathered speakers and panelists from the Government, Industry, and Academia with the expertise to have an honest dialogue about potential barriers standing in the way of achieving this vision along with strategies and actionable solutions. In particular several of the sessions will be structured as a point-counterpoint panel to fully consider each objective of the vision. NDIA Conference Website

What are some of the technologies that, to you, really set the stage for these emerging trends? How do you foresee them having an impact on our frontlines?

I think that some of the game-changing technologies that will be emerging over the next few years include: power, actuation, perception, and autonomy software.

What role does RE2 play in this scenario?

RE2 is pushing the envelope of affordable, intelligent, mobile manipulation systems, helping to define what is possible, which in turn will help generate requirements for this growing industry. By making these systems be affordable, RE2 is creating more possibilities for the future of acquisition as well as increasing ROI.

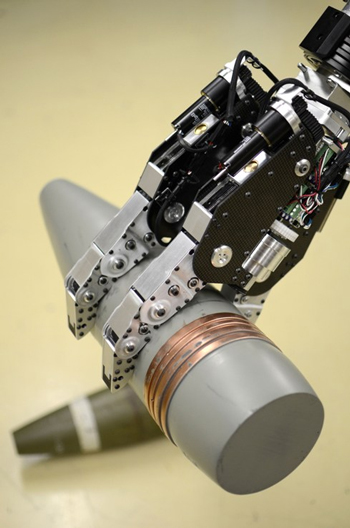

RE2's three-fingered Conformal End Effector (CE2). There is a 5-lb version and a 12-lb version. The 12-lb version is shown in the image. This has 11 degrees of freedom. It can support a pinch, grasp, or curl. Each finger can exert over 120 lbs of force! It has the dexterity to pinch a small wire and the strength to pick up a 100-lb 155mm shell.

How would these developments and the expenditure of these resources help other industries involved in robotics?

RE2 is focused on making its systems modular, not only for the US Military, but for other markets, such as the Public Safety market. Just as the USB standard interface was created for the PC industry, RE2 is helping to define the standard interfaces that will be used by robots both within the DoD and within other markets. Secondly, in addition to making its mobile manipulation systems affordable and intelligent, RE2 is moving the bar in terms of power-density, dexterity, and intuitive control. These advancements have the ability to penetrate new markets (e.g. healthcare) as well as transform existing markets (e.g. industrial automation).

RE2's DS1-MA manipulator mounted on a Macro USA Armadillo. A great example of modularity. Two vendors, two products, one system to solve a need.

Do you envision a day where man and robot fight side by side on our frontlines?

In a way, man and robot are already fighting side by side today. However, the robot has the tougher end of the relationship! The robot is the one entering caves to gain reconnaissance information, for example, while the person remains at a known, safer location. How these robots fight side by side, however, will change and improve over time. In a previous Ground Robotics Capabilities Conference and Exhibition, LTG Lynch (US Army Retired) talked about scenarios where man and robot fight side by side. One of those scenarios was the "robotic wingman". In this scenario, the robot is like an intelligent robotic mule, carrying ammunition and supplies, mirroring the movements of dismounted troops, providing supplies to those who need it, etc.

About Robotics Engineering Excellence (RE2, Inc.),

located in Pittsburgh, PA, is a Carnegie Mellon spin-off specializing in agile defense robotics with an emphasis on intelligent modular manipulation for mobile robotic platforms. As a defense contractor, RE2 has programs to develop mobile robotic technologies for the Army, Navy, Air Force, DARPA, Robotics Technology Consortium, and TSWG.

About the 2012 NDIA Ground Robotics Capabilities Conference

About the 2012 NDIA Ground Robotics Capabilities Conference

NDIA knows Warfighter needs are changing, and so does the Department of Defense. The purpose of the 2012 Ground Robotics Capabilities Conference & Exhibition is to provide a forum for Industry and Government to have an honest dialogue for identifying the technologies that will be able to meet the future needs of the Warfighter. For up-to-the-minute conference updates, follow @NDIA_Robotics on Twitter!

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product