If a barcode or marking is unreadable, it can result in recalls, unhappy customers, and even fines. It is important to identify these issues early by implementing regular checks and verification to ensure quality.

Contributed by | Microscan

Coding and Marking Challenges

Most of the items we use or consume contain various codes and markings, from best-before and lot dates to EAN or Data Matrix barcodes to serial batch numbers and various unique identifiers. These markings are there to ensure traceability and product safety, to protect consumers, and to avoid counterfeiting. They are regulated by various global and national laws, standards, and guidelines. As manufacturers aim to meet the increased demand for product identification and brand protection, they are implementing coding and marking equipment in their factories and throughout their supply chain.

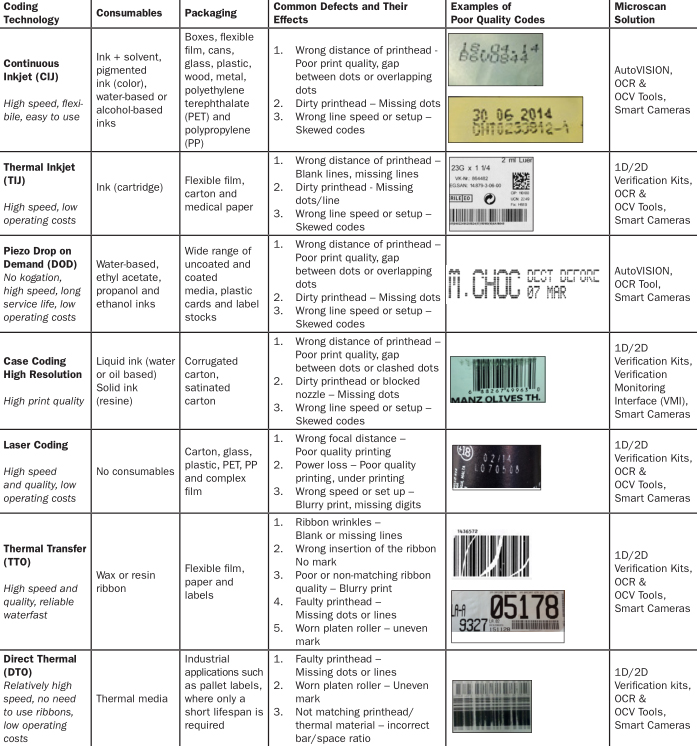

There are many different print techniques that manufacturers can choose such as continuous inkjet, thermal transfer, and laser coding. All of these techniques have their unique advantages and challenges. This white paper describes the most common print techniques in industrial applications, the most common challenges, and the effect these challenges can have on print and code quality.

If a barcode or marking is unreadable, it can result in recalls, unhappy customers, and even fines. It is important to identify these issues early by implementing regular checks and verification to ensure quality.

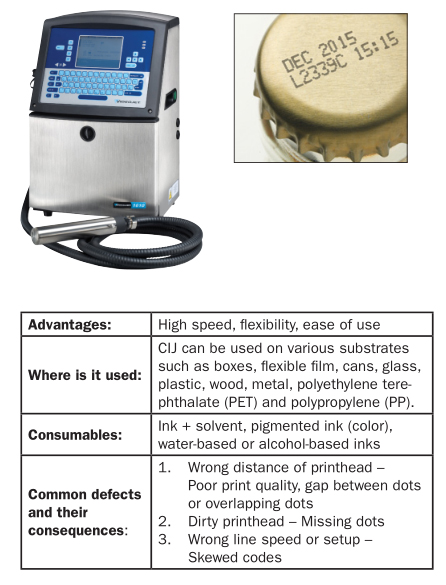

Continuous Inkjet (CIJ)

How it works:

In CIJ technology, a high-pressure pump directs liquid ink from a reservoir through a gunbody and a microscopic nozzle, creating a continuous stream of ink droplets. A piezoelectric crystal creates an acoustic wave as it vibrates within the gunbody and causes the stream of liquid to break into droplets at regular intervals. The ink droplets are subjected to an electrostatic field created by a charging electrode as they form. This results in a controlled, variable electrostatic charge on each droplet.

The charged droplets pass through an electrostatic field and are deflected by electrostatic deflection plates to print on the substrate, or allowed to continue on to a collection gutter for re-use. Only a small fraction of the droplets is used to print, the majority being recycled.

CIJ is one of the oldest inkjet technologies in use. The major advantages are the very high velocity of the ink droplets, which allows for a relatively long distance between printhead and substrate, and the very high drop ejection frequency, allowing for high-speed printing. Another advantage is freedom from nozzle clogging as the jet is always in use, therefore allowing volatile solvents such as ketones and alcohols to be employed, giving the ink the ability to “bite” into the substrate and dry quickly.

The ink system requires active solvent regulation to counter solvent evaporation during the time between nozzle ejection and gutter recycling, and from the venting process.

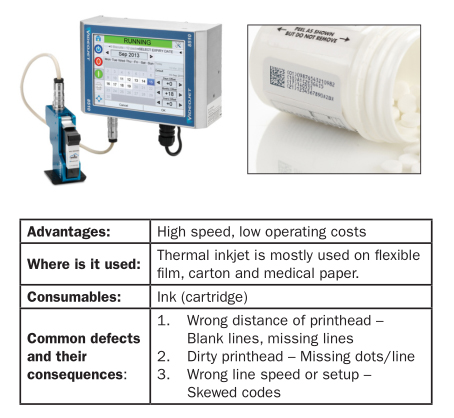

Thermal Inkjet (TIJ)

How it works:

In the thermal inkjet process, the print cartridges contain a series of tiny chambers, each containing a heater, all of which are constructed by photolithography. To eject a droplet from each chamber, a pulse of current is passed through the heating element causing a rapid vaporization of the ink in the chamber to form a bubble, which causes a large pressure increase, propelling a droplet of ink onto the paper.

The inks used are usually water-based and use either pigments or dyes as the colorant. These inks must have a volatile component to form the vapor bubble, otherwise droplet ejection cannot occur. The thermal heater cools and the vacant ink channels are replenished with filtered ink. This cycle can repeat up to 6,900 times per second. As no special materials are required, the print head is generally cheaper to produce than in other inkjet technologies.

Thermal printers use disposable print cartridges that contain both the ink supply and the print head. Typically, these cartridge- driven units produce excellent print quality at 300-600 dpi but the higher print quality results in slower print times.

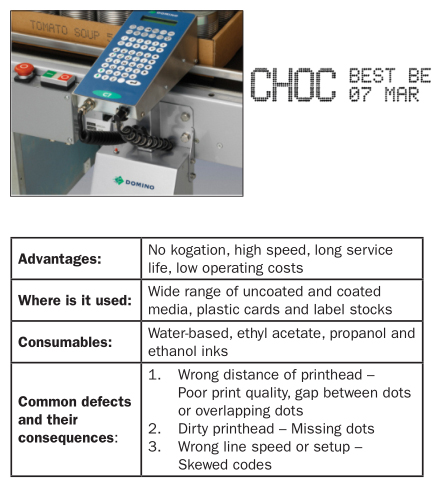

Piezo Drop on Demand (DOD)

How it works:

Piezo DOD printing, in contrast to thermal inkjet, uses a permanent printhead. Most commercial and industrial inkjet printers and some consumer printers use a piezoelectric material in an ink-filled chamber behind each nozzle instead of a heating element. When a voltage is applied, the piezoelectric material changes shape, which generates a pressure pulse in the fluid forcing a droplet of ink from the nozzle. Piezoelectric inkjet allows a wider variety of inks than thermal inkjet as there is no requirement for a volatile component, and no issue with kogation (buildup of ink residue), but the print heads are more expensive to manufacture due to the use of piezoelectric material. The piezoelectric process does not utilise heat, which expands the cartridge life of these printers.

A DOD process uses software that directs the heads to apply between zero and eight droplets of ink per dot and only where needed. DOD technology is often used on production lines to mark products. For instance, the “use-before” date is often applied to products with this technique; in this application the head is stationary and the product moves past it. The advantages of this technique are high speed, a long service life, a relatively large gap between the print head and the substrate, and low operating cost.

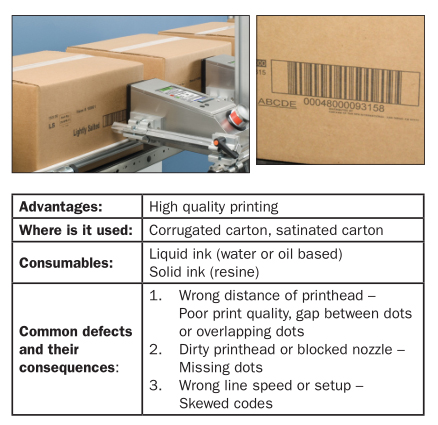

Case Coding (High Resolution)

How it works:

Legible and accurate codings on cases and cartons are critical for inventory and supply chain management. Various high- resolution ink-based systems are available to mark text or codes directly on cases. An ink-based system eliminates the need for labels.

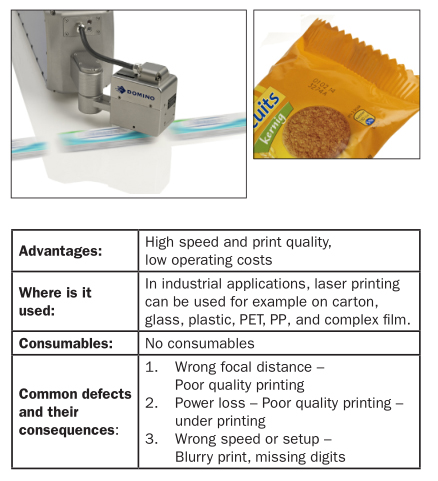

Laser Coding

How it works:

Laser marking is achieved by using a laser system to etch or vaporize the surface layer of the material leaving an indelible permanent mark. Scribing laser coders can mark text, graphics, and variable data onto a variety of substrates including plastic, glass, paper, and cartons. As there are no inks or fluids used, laser systems are environmentally friendly and cost-efficient.

Laser technology uses a concentrated beam of light which is deflected by mirrors that are controlled by galvanometer assemblies. The galvanometer technology enables laser coding and marking onto moving or static products from low to high speeds.

Laser marking and coding function by removing material or coating from the product or packaging. This permanently changes the surface of the substrate. For example, when laser coding a painted card, the very top layers of paint are removed, revealing the contrasting bare card underneath. The same process on plastic changes the chemical nature of the material, either melting it to leave a mark or causing a color change. When coding on glass, the laser leaves micro cracks, scribing a permanent code without weakening the material.

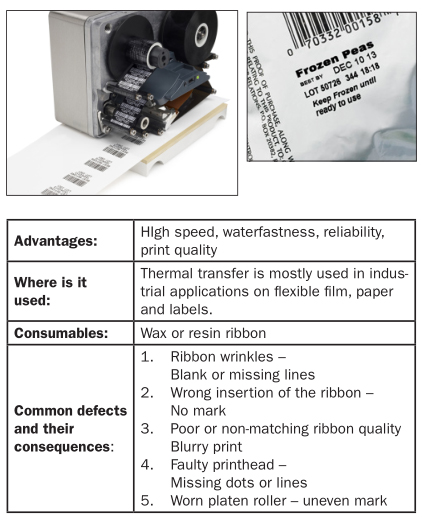

Thermal Transfer (TTO)

How it works:

Thermal transfer overprinting is a digital printing process in which material is applied to paper or other material by melting a coating of ribbon so that it stays glued to the material on which the print is applied. It differs from direct thermal printing where no ribbon is present in the process.

The paper and ribbon travel beneath the thermal printhead, and the wax-based ink from the transfer ribbon melts onto the paper. When cooled, the wax adheres permanently to the paper.

This type of thermal printer uses a panel of ribbon of equal size to each page to be printed, regardless of the contents of the page. Monochrome printers have a black panel for each page to be printed, while color printers have either three (CMY - cyan, magenta, and yellow) or four (CMYK - cyan, magenta, yellow, and black) colored panels for each page. Although acceptable in quality, the printouts from these printers cannot compare with inkjet printers and color laser printers. This type of printer is often employed for industrial label printing due to its waterfastness and speed. These printers are considered highly reliable due to their small number of moving parts.

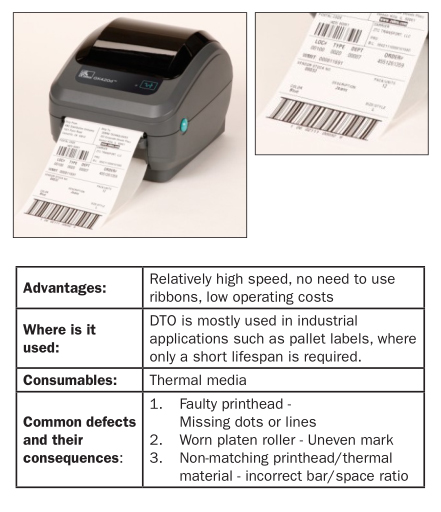

Direct Thermal (DTO)

How it works:

Direct thermal overprinting is similar to the thermal transfer digital printing process but does not use a ribbon. This means that the media must be heat-sensitive so that the mark can be placed directly onto the material or label. Direct thermal media is more sensitive to light, heat, and abrasion, reducing the life of the printed material.

What can you do to ensure print quality?

Regardless of the print or marking technique used, the first step in ensuring print quality is identifying potential issues. It is important to implement regular checks to prevent these issues from becoming significant problems. Checks can be done manually, but these are prone to human error. In an automated system, a barcode reader can be used to ensure code readability, or an inline verification system can be implemented to verify the code or text quality in real time. Microscan manufactures compact and powerful barcode readers, smart cameras, and industrial lighting to help you ensure print quality, product safety, and product traceability.

More Microscan product information and training resources are available at www.microscan.com.

Overview of Print Techniques and Their Challenges

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product