Compact, high-torque motors precisely control biopsy needle to improve speed, efficiency, and radiation exposure.

Contributed by | Micromo

It started out with a simple question one day during Dr. Rajiv Gupta’s residency at Massachusetts General Hospital (MGH): Why, with CT scanners routinely achieving sub-millimeter resolutions, was he still performing manual needle biopsies with only centimeters of accuracy? There had to be a better way. A team from the Massachusetts Institute of Technology (MIT) agreed and built a robotic biopsy system with unprecendented efficiency and accuracy, powered by compact, high-torque motors from MICROMO Electronics.

The procedure for lung biopsies today is to use snapshots from a CT scanner to manually direct a 10- to 20-cm needle from the skin surface into a suspect lesion. An initial scan determines the desired entry point for the needle. Next, the physician pushes in the needle, takes an image, adjusts the needle, takes another image, and so on -- for typically about 10 iterations. The process is time consuming, lacks precision, and subjects the patient to repeated doses of ionizing radiation. Gupta, now director of the Volume CT Laboratory at MGH, thought a robotic system could improve targeting accuracy and speed the process, while reducing x-ray exposure.

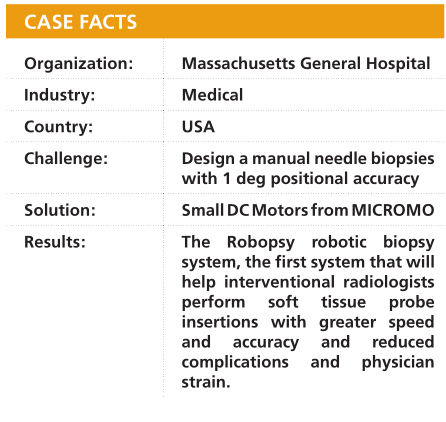

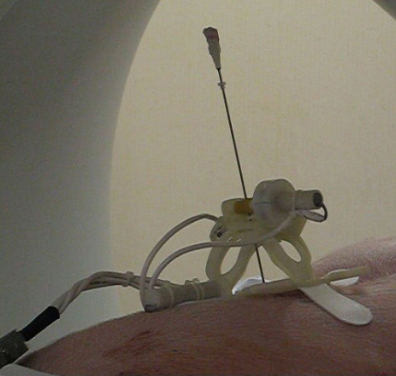

Powered by compact, high-torque servo motors, the Robopsy robotic biopsy system performs needle biopsies efficiently, reducing patient exposure to radiation and improving resolution. (Courtesy of Nevan Hanumara and Conor Walsh)

Enter MIT doctoral candidates Nevan Hanumara and Conor Walsh, who connected with Gupta via the Center for the Integration of Medicine and Innovative Technology (CIMIT), under the sponsorship of Professor Alexander Slocum’s graduate precision machine design class. Developed by a consortium of Boston-area academic institutions and hospitals, CIMIT is designed to bridge the gap between medicine and engineering. The MIT team began work on the project in 2004; the result is the Robopsy robotic biopsy system, now in the animal testing stage.

Controlling the needle

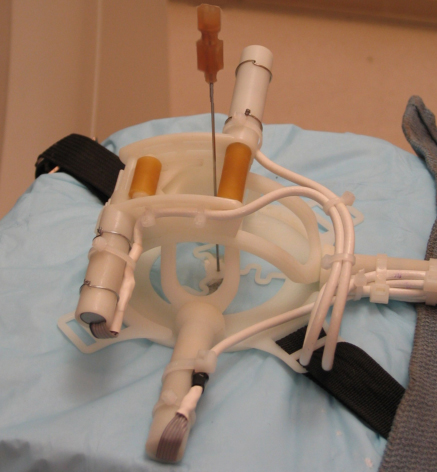

The Robopsy design consists of two long, narrow hoops shaped something like the peel of an orange section and nested concentrically with their long axes set orthogonal to one another. The overlap of the two hoops essentially forms a cage that encloses the needle. A carriage fixed to the inner hoop and riding atop the outer hoop frames the cage and provides the means to adjust the needle. Actuators revolve the hoops about their long axes. That motion shifts the carriage, which in turn moves the needle in polar coordinates: q (left to right in patient frame of reference) and f (head to toe in patient frame of reference).

Robopsy robotic biopsy system consists of two hoops (tan and purple) set orthogonal to one another and revolving about their long axes. A carriage that rides atop the hoops encloses the needle (top). A pinion-driven roller (red, left) drives the needle against a passive roller (red, right), which rotates to drive the needle into the lesion.

To minimize tissue damage caused by movements of the needle while the patient breathes, the default state is for the needle to wobble freely within the carriage. When it comes time to adjust the needle in q and f and to move it radially, a pinion-driven gripping roller presses the needle against a passive roller on the side of the carriage. Once the needle is pinned, the passive roller rotates to position the needle radially with respect to the patient’s skin.

Tests revealed that a typical 19-gauge biopsy needle requires 3 to 5 N of force to penetrate the pleura (the sac surrounding the lungs). The diameter and coefficient of friction of the gripping roller required a torque of 200 Nm^2 to hold the needle so that it can be driven in with sufficient force. Accordingly, the team designed the system to produce a maximum force of 10 N. The design incorporates four micro-servo motors: one to orient each hoop, one to power the pinion drive for the gripping roller, and one to rotate the passive roller. Each 10-mm-diameter motor couples to a 10-mm-diameter gearbox with a 256:1 reduction ratio to achieve the desired torque and speed. Small encoders mounted to the posterior end of the motors provide closed-loop positional control.

Lung biopsies take place while patients are only lightly anesthetized, which imposed certain limitations on the design. One was size. The Robopsy package needed to be lightweight and small enough to be affixed securely to the chest of the patient. To maximize range of motion, the team wanted the pivot point of the needle to be near the entry point on the skin. All of this necessitated the use of compact motors. “We really needed quite a high torque in a small package,” says Walsh. “The other constraint was that we needed a small diameter because we designed our device to be as close to the patient surface as possible, so having motors that were only 10 mm in diameter was really beneficial for us.”

Big challenges in tiny packages

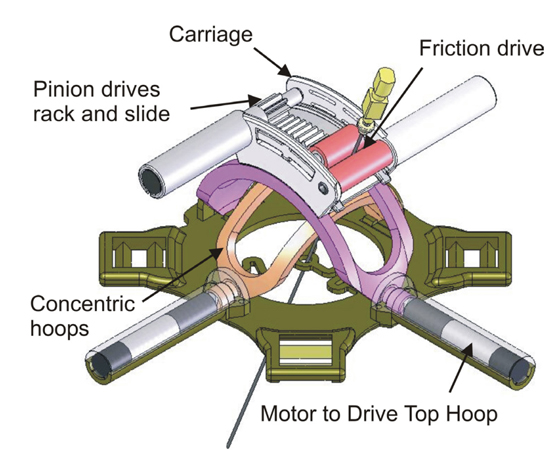

The team built most of the unit of disposable, injection molded, radiolucent plastic parts. An actuator module of four servo motors and their associated control electronics powers the plastic elements and can be retained and reused. To maintain the disposables and ensure that none of the elements in the package atop the patient’s chest interfere with imaging, the motors are displaced from the hoops.

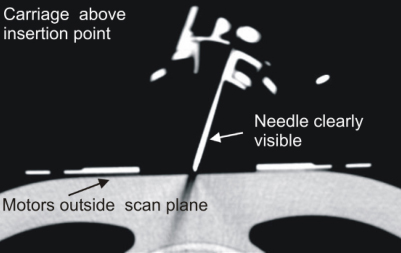

CT image shows that motors and non-radiolucent portions of the Robopsy unit do not interfere with visibility of needle. (Courtesy of Nevan Hanumara and Conor Walsh)

Connecting the motor to the load required custom couplings, though, which was where MICROMO’s in-house machine shop came in. “When you’re dealing with a very tiny motors, there are always two challenges: getting a grip on the motor and getting something on the shaft,” says Hanumara. “We had to have custom couplings laser welded onto the shaft.”

“That allowed us to easily and securely transfer the torque from the motor to the device,” Walsh continues. “We drew up specifications for a coupling and we designed the mating feature into our plastic parts. We sent those couplings to MICROMO with the drawings and they laser welded them on for us. They were very helpful,” he adds.

System performance

In conjunction with MGH, the team has so far tested the system with gelatin phantoms and a porcine subject. To minimize radiation dosage, the unit operates in near-real time, in an iterative process reminiscent of the manual approach -- only more efficient. The pre- procedure scan provides the data to plan the desired needle path prior to affixing the Robopsy device. With the device and needle in place, the second scan allows the system to register the needle and identify the specific angles and depth of its desired insertion. Once that data is transferred into the Robopsy interface, the unit inserts the needle up to the pleura. A third scan permits final angular adjustments to insert the needle into the lesion. A fourth, and final scan confirms that the needle is in place. “What we have from our first porcine trial is a very good validation,” says Hanumara. “We’ve confirmed that could be done.”

“It worked straightforwardly the first time,” agrees Walsh. “It’s really properly exploiting the precise positional information that’s available from the imaging machine.

The radiologist performs the procedure remotely from the control room, shielded from the radiation, and in doing so they can do it in a reduced amount of time and also with a lower dose of radiation per patient.”

Porcine trials of Robopsy were successful and demonstrated the ability to target a 1-cm suspect lesion. (Courtesy of Nevan Hanumara and Conor Walsh)

The system is designed to achieve 1 deg positional accuracy, which currently translates to the ability to target a 1-cm lesion. The eventual goal, Hanumara says, is to reach 0.5-cm accuracy. This would allow doctors to target different regions of a lesion, since the histology of lesion can change with position. The team has more ambitious plans than that, though. “We see this as the first in a family of devices,” Hanumara says. “We start with a biopsy of the lung, we move into biopsies of other organs, maybe we can then get into targeted treatments. We can also look at where else you can use lightweight, low-cost robotics to substantially improve accuracy.”

One thing is certain, they’re not only satisfied with their system, they’re satisfied with their motors and their motor supplier. MICROMO showed no reluctance at supplying the small quantities the team sought, says Walsh. “It was the exact opposite with them. It was always, ‘What can we get you that’s going to do what you need?’ That was their primary concern.”

“When I go out in the workplace and I need to put equipment together, there are certain companies I’ll recommend and there are companies I wouldn’t touch with a ten foot pole,” says Hanumara. “I would not hesitate to recommend MICROMO for good motors, briskly, with a proper selection.”

Inside the Solution

With $9 million dollars in inventory and a wide range of part numbers, MICROMO was able to supply the exact motors the MIT team needed. “They actually provide the motors that are in their catalog, and it’s been our experience that not all motor companies actually do,” says Hanumara. “They’ll say, ‘Well, we have this other product’ and you’ll say, ‘But what about this motor that meets all our specs?’”

MICROMO had the motors that met their specs, and a dedicated machine shop that customized the product by adding couplings.

- 1024...S DC Motor with precious-metal commutation and a rear shaft to mount an encoder, drives the hoops and rollers. Motor Specs: 10-mm diameter, 1.11 W output power, 1.28 mNm of torque, 12,000 rpm.

- 10/1 Planetary Gearhead, at 256:1 ratio fitted with ballbearings, to achieve the required torque, Gearhead Specs: 19.1 mm long, less than 3% backlash.

- HEM Encoder to track motion precisely, an encoder (10 pulse pre quadrature, 40 pulse post quadrature)

About Micromo

For over 50 years, MICROMO (FAULHABER Group) has brought together the widest range of high quality, high performance linear and rotary motion solutions, decades of micro motion expertise based on dc motor technology and full service design, sourcing and manufacturing capability on a global basis to deliver benchmark motion solutions. Call MICROMO at 800-807-9166 and let one of our Application Engineers, design a custom motion solution for your next application.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

FAULHABER MICROMO

Since 1961, FAULHABER MICROMO has partnered with OEMs to deliver high precision, high performance, custom micro motion system solutions to markets such as medical, robotics and automation in North America. FAULHABER MICROMO's tradition of innovation started decades ago in Germany. The groundbreaking invention of the FAULHABER coreless winding started it all for a market that produces millions of motors today. How can the FAULHABER MICROMO team help you deliver your next innovation to market first? Learn more about MICROMO's solutions for the most demanding applications, our diverse motion products and technologies, online ordering, Engineering and R&D teams, Clean Room Assembly, Machining Center and other services at our Clearwater, FL facility at https://www.faulhaber.com.

Other Articles

Walking naturally with artificial foot

Testing drive systems virtually - Simulink library for development and digital twin.

At least 60 million strokes

More about FAULHABER MICROMO

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product