The mission of my lab is to discover new types of materials that will allow machines, robots, and electronics to be more compatible with our everyday environment.

Carnegie Mellon Research - Invisible, Stretchable Circuits

Carmel Majidi | Soft Material Lab Carnegie Mellon University

Why are your findings important? Who will benefit from this technology in the near term?

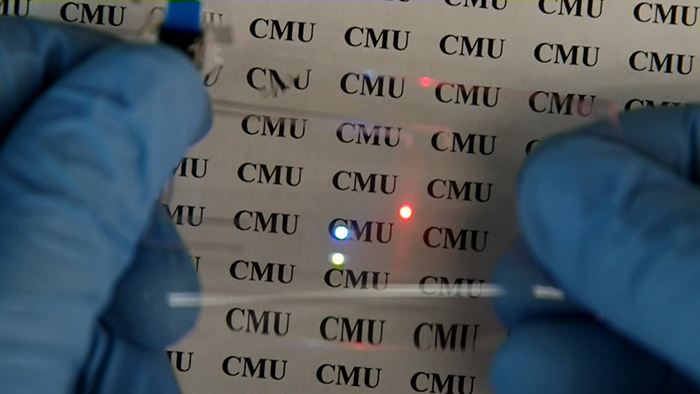

For the first time, we demonstrate a method to create circuits that are highly conductive, thin, lightweight, soft, stretchable, and optically transparent. This breakthrough will allow electronics to be attached to skin, clothing, or accessories without altering its look or feel. In the near term, we think this technology will be useful for creating electronic stickers that can attach to a wide range of surfaces — from soft tissue to curved 3D shapes — and support basic circuit functions like touch detection, RFID, and visual alerts. This will be of greatest benefit to consumers and designers looking to use electronics in a way that’s both visually and mechanically invisible.

Transparent, soft and highly stretchable conductors are needed in next-generation technologies for wearable computing, soft-bioelectronics, and bio-inspired robotics.

Credit: Carnegie Mellon University’s College of Engineering

How could these findings be useful for future technologies 10 or 20 years from now?

As wireless electronics continue to proliferate, it’s important to design them in a way that doesn’t obstruct the natural aesthetics and functions in our environment. While miniaturization is one way to accomplish this, some applications like touch screens and antennas require large area coverage. In this work, we introduce an approach to create electronics that are optically transparent, thin, lightweight, soft, and highly stretchable. They can conform to skin, deformable substrates (like balloons), and 3D surfaces without causing damage or restraining motion. They are also optically clear and invisible so that they don’t obstruct our view.

What are some current applications where the technology could be used?

In the study we showed two potential applications. The first is an invisible proximity sensor that can be placed on everyday 3D objects. For the example in the paper, the sensor causes a light to turn on when a hand comes in close contact with a beaker that contains hazardous material. Optical transparency is important so that the sensor doesn’t cover up the hazardous contents of the beaker. For the second application, we show how the circuit could be placed over a spherical camera and display colors that correspond to the intensity of pollutants in the surrounding environment. The use of a spherical “eye-ball” camera is supposed to mimic the application of our technology for an electronic contact lens that is see-through but that also contains embedded micro electronics for visual display.

What technical challenges did you have to overcome to create this technology?

The biggest challenges have to do with materials selection and microfabrication. Because the circuit has to be invisible, soft, and stretchable, we can’t use conventional printed circuit boards. Instead, we had to come up with a new technique that uses laser to rapidly pattern thin films of a soft conductor on a clear rubber sheet. The conductor is a non-toxic metal that is liquid at room temperature and has superior conductivity, deformability, and manufacturability compared to other soft conductive materials.

Did you discover anything that could help with solving other problems in science and engineering?

Our choice of materials and manufacturing method is exciting because it allows for rapid and inexpensive creation of digital circuits that are soft and mechanically robust. This approach represents a breakthrough in the field of electronics rapid prototyping since it allows people to design and produced their own customized stretchable electronics without needing to use industrial facilities like a chip foundry or clean room.

Your lab brings together researchers from different academic backgrounds. What is the value of having a multidisciplinary approach to problem-solving within your field?

The mission of my lab is to discover new types of materials that will allow machines, robots, and electronics to be more compatible with our everyday environment. Progress in this area requires expertise in materials engineering, the mechanics of soft materials, computing, and robotics. No one person can have expertise in all of these areas. Instead, it’s essential that my lab brings together students and researchers from a variety of different engineering and scientific backgrounds.

You’re using laser-based rapid prototyping tools to create these materials. Does this mean that people could eventually produce these technologies on their own? In general, what new opportunities do you envision as rapid prototyping continues to advance?

Laser-based rapid prototyping is exciting because it is very fast and can be done with machines that are inexpensive and portable. The types of lasers that we use are for industrial-grade electronics prototyping but could eventually be replaced with cheaper desktop units that, like laserjet printers today, people could have in their own homes. That would allow consumers to print their own electronics off of designs that they create on their own or buy online.

Are there other aspects of this research that you would like to discuss here?

This work was a collaboration between my lab at CMU and Prof. Peter Herman’s research group at the University of Toronto. It was a wonderful opportunity to demonstrate a new technology and also learn more about how lasers can be used to precisely pattern thin films of liquid metal.

About Prof. Carmel Majidi

My career mission is to discover materials, hardware architectures, and fabrication methods that allow robots and machines to behave like soft biological organisms and be safe for contact with humans. The aim is to replace the bulky and rigid hardware in existing robots with soft, lightweight, and deformable technologies that match the functionality of natural biological tissue. Currently, my group is focused on filled-elastomer composites and soft microfluidic systems that exhibit unique combinations of mechanical, electrical, and thermal properties and can function as “artificial” skin, nervous tissue, and muscle for soft robotics and wearables. I’m particularly interested in approaches that are practical from a rapid prototyping and robotics implementation perspective. This includes efforts to enable robust mechanical and electrical interfacing between soft-matter systems and conventional microelectronics and hardware.

My career mission is to discover materials, hardware architectures, and fabrication methods that allow robots and machines to behave like soft biological organisms and be safe for contact with humans. The aim is to replace the bulky and rigid hardware in existing robots with soft, lightweight, and deformable technologies that match the functionality of natural biological tissue. Currently, my group is focused on filled-elastomer composites and soft microfluidic systems that exhibit unique combinations of mechanical, electrical, and thermal properties and can function as “artificial” skin, nervous tissue, and muscle for soft robotics and wearables. I’m particularly interested in approaches that are practical from a rapid prototyping and robotics implementation perspective. This includes efforts to enable robust mechanical and electrical interfacing between soft-matter systems and conventional microelectronics and hardware.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Featured Product