Our focus in this article is on the creation of customized automated workholding and material-handling solutions and the steps that must be completed from drawing board to final construction in order to ensure that the needs of the end user will be successfully met.

Maximizing the Benefits of Customized Solutions

Maximizing the Benefits of Customized Solutions

Gary Michels is Manager, Applications Engineering | DESTACO

The lives of manufacturers would be so much easier if all of their automation processes were homogeneous. Unfortunately, there are many that require customization in order to satisfy the unique requirements of an automated workholding or material-handling application. This is the case for any application that involves some combination of manual clamps, end effectors, grippers and indexers.

At this point, it serves to acknowledge that there is a significant difference between a customized “product” and a customized “solution,” and we must warn that using the terms interchangeably is not correct or recommended.

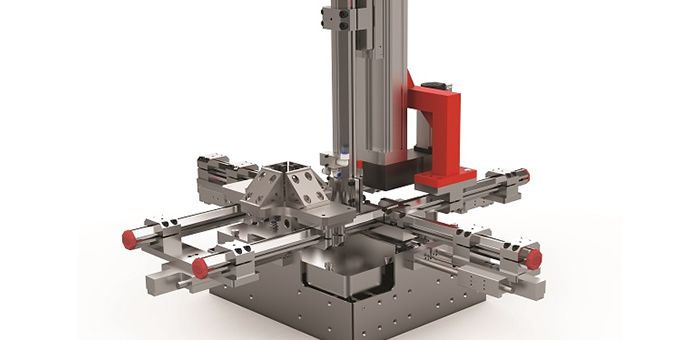

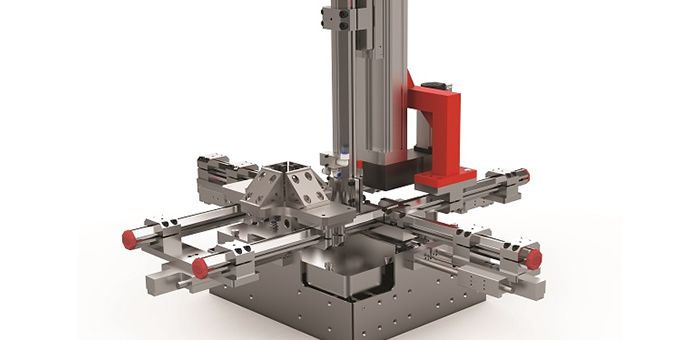

A customized product is a component that has been modified to fit the needs of a specific application. On the other hand, a customized solution takes components from different families of products – some of which may, indeed, have been customized – and pieces them together into a solution that satisfies the needs of the application. Differentiating between the two is similar to knowing that while all champagne is sparkling wine, not all sparkling wine is champagne.

Our focus in this article is on the creation of customized automated workholding and material-handling solutions and the steps that must be completed from drawing board to final construction in order to ensure that the needs of the end user will be successfully and reliably met.

COMMUNICATION IS KEY

The process of creating a customized solution begins when the end user reaches out to the designer of the proposed solution. Most important is describing what will need to happen in the delivery process or, simply, what needs to be moved from Point A to Point B. Within that process, the designer also needs to know the weight, size and shape of the object that needs to be moved, as well as the speed at which the procedure needs to be completed.

Other process variable-related questions that may need to be communicated to the designer can include:

- Are 3D CAD files available?

- Are samples available?

- Is the material to be handled porous?

- Is the material toxic, hazardous or dangerous?

- Are cell layouts available?

- Will multiple tools be required?

- Are any videos or pictures of the cell running available?

- Do any regulatory specifications or standards need to be met?

Admittedly, there will likely be some back and forth between the designer and end user at this stage since the customer may only have a vague idea or simplistic outline of what the final customized solution may need to look like or the tasks it will need to perform. This is where asking the right questions from the designer can help all of the pieces fall into place.

To aid the information-gathering process, many designers of customized workholding and material-handling products have created forms that can be filled out by the customer. These so-called “Solutions Forms” allow the customer to supply basic information about the process (Picking up from? Dropping off to?), along with specific information regarding, for example, what type of automation (robot, gantry, crane, etc.), tool-changing (manual, auto, none) and vacuum (venturi, port only, ARV, etc.) systems will be used.

All of the information that is gathered in the initial communication phase will be used by the designer to determine which components are needed (and if any of them will need to be customized) to build the final customized solution.

FIVE STEPS TO SUCCESS

Once all of the preliminary background work has been completed and the sources for the components identified, a five-stage process begins that will lead to the creation of an engineered drawing and conceptualized model that will serve as a blueprint for the construction of the final customized solution.

- 1. A proof-of-concept drawing is created that is around 80% factual and notes all of the ranges that the tool needs in order to function to the end-user’s specs. Providing a drawing to review is easier than trying to verbally explain the system to the customer. The customer will review this drawing and let the designer know if it meets the operational parameters that are required, knowing that modifications can be suggested and revisions made. When the proof-of-concept drawing is approved, the designer can provide the customer with a preliminary timeline and budget that will be needed to bring the project to completion.

- 2. When the customer signs off on the design, the actual design phase is initiated, which, depending on the complexity of the solution that needs to be built, can typically last from four to eight weeks.

- 3. Once the customer delivers the purchase agreement, the designer verifies the scope of work (in a process known as a “0% kickoff” review) that will need to be performed, which is a confirmation of the specs that were spelled out in Step 1.

- 4. Design reviews are provided at key project milestones in order to ensure that all required parameters for fit, form and function of the final solution will be met, as well as the timeline for completion. Many designers will also use standard timeline documents that indicate desired Duration and Start and Finish dates for a wide array of project-related tasks and whether or not those schedules have been met. If needed, modifications are made, which may or may not require a revised RFQ.

- 5. When the design has been roughly 50% completed the designer provides 2D drawings and a Bill of Materials (BOM) for the the system, along with all electrical and/or pneumatic schematics. These drawings are either approved by all parties or undergo further modifications. If the drawings are approved, the project is released into the manufacturing phase, with constant timeline updates provided to keep all constituencies apprised of the solution’s progress toward completion.

At the end of the manufacturing phase the customer is brought in for 100% build review and given an opportunity to see the customized solution function in a real-world application. At this time, the designer will take quality-check photos or videos of the completed solution, which will be used to compare the operation of the completed project to its intended original design. When operational approval – or “buy-off” – is given by the end user, the finished solution, along with an Installation, Operation and Maintenance (IOM) manual and parts list, is shipped to the customer’s plant for installation and deployment in the automated workholding or material-handling process.

BENEFITS OF CUSTOMIZED SOLUTIONS

As mentioned, consistent communication between the designer, suppliers and end user is critical if a customized solution can be created that meets the needs of the workholding or material-handling application. Working with a qualified custom-automation expert – in addition to delivering the needed solution – can also have some ancillary benefits that can lead to a strong, trustworthy partnership between the designer and end user, including:

- Give the customer the ability to complete the system design faster, by leveraging a custom-automation expert to design and build a portion of the machine for them

- Provide expertise on custom-automation applications that the end user may not have previously been familiar with or aware of

- Deliver a top-of-line customized solution that the end user could have struggled in developing alone

- Create a solution that will ultimately enhance the end user’s operational throughput and reduce operational costs, leading to an improved reputation within the industry and a stronger bottom line

- Establish a baseline of trust and reliability between the designer and end user that can be used as the foundation for future customized-solution projects

CONCLUSION

While variety may be the spice of life, for manufacturers who rely on automated workholding and material-handling equipment in their processes, any deviation from the norm can present challenges. When a customized solution is required, manufacturers can benefit by working directly with designers who are experienced and adept at taking an idea and creating a blueprint that will result in a finished solution that meets every need.

The keys are open lines of communication from first contact to finished product, and selecting a partner who has experience with customization. When end users, designers and suppliers work in harmony, the result will be the timely creation of a customized solution that is of the highest quality. And the ultimate success is a solution that meets all of the end user’s needs that leads to optimized production schedules and streamlined operational costs.

About Gary Michels

Gary Michels is Manager, Applications Engineering for Destaco, and can be reached at gmichels@destaco.com. Destaco, a Dover Corporation company, is a global leader in the design and manufacture of high-performance automation, workholding and remote-handling solutions. Headquartered in Auburn Hills, Michigan, U.S.A., Destaco serves customers in a variety of end-markets, including the automotive, life sciences, consumer packaged goods, aerospace, industrial and nuclear sectors.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

DESTACO

DESTACO is now the worldwide leader in the innovation, design, manufacture and support of clamping, gripping, transferring, indexing and robotic tooling solutions for workplace and automation needs.

Other Articles

Automate 2025 Q&A with DESTACO

DESTACO Smart Electric Product Line of Clamps and Guides

Talking AUTOMATE 2024 with DESTACO

More about DESTACO

Featured Product