On the camera side, the Fraunhofer Institute relies on two uEye FA industrial cameras from IDS. The robust and resilient models with PoE are ideal for demanding environments.

Picking the right chart - (Semi-)Autonomous surface and underwater mapping for rivers and lakes

Case Study from | IDS Imaging

Up-to-date and accurate maps of the waterways are a prerequisite for safe and efficient shipping in Germany. Authorities such as the Federal Maritime and Hydrographic Agency, but also private harbor operators, are obliged to provide these in an up-to-date form at all times. The main reason for this is to avoid accidents caused by an incorrect or outdated chart. This includes the classification of federal waterways, their kilometers, existing locks, lifting and barrages, other surrounding waters, places and borders. Currently, mapping is carried out by conventional ships with trained personnel, which is time-consuming and expensive. This can result in long intervals between measurements at a particular location.

(Semi-)automated monitoring of waterways by autonomous platforms with obstacle avoidance and traffic detection could optimize this process and provide maps in less time. To this end, the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB has developed an autonomous surface vehicle capable of autonomously surveying bodies of water as part of a three-year in-house research project. For this purpose, the riverbed is recorded using sonar. Furthermore, the bank areas and surface structures are monitored by an optical system with two integrated industrial cameras from IDS Imaging Development Systems GmbH. The information obtained in this way is then merged and transferred to a 3D map of the surroundings.

(Semi-)automated monitoring of waterways by autonomous platforms with obstacle avoidance and traffic detection could optimize this process and provide maps in less time. To this end, the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB has developed an autonomous surface vehicle capable of autonomously surveying bodies of water as part of a three-year in-house research project. For this purpose, the riverbed is recorded using sonar. Furthermore, the bank areas and surface structures are monitored by an optical system with two integrated industrial cameras from IDS Imaging Development Systems GmbH. The information obtained in this way is then merged and transferred to a 3D map of the surroundings.

Application

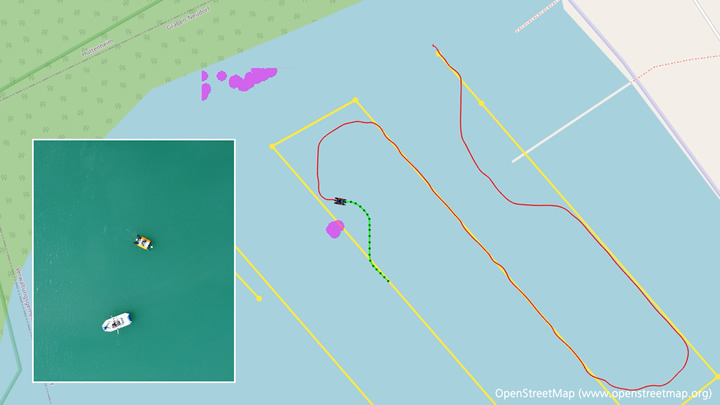

The precise surveying of water bodies is a demanding task. TAPS, the Fraunhofer IOSB's semi-automatic direction finding system for rivers and lakes is able to perform this task both under and above water. The vehicle, which measures approximately 2 x 1.5 x 1 meters, travels along the relevant waterway and automatically avoids obstacles, whether stationary or moving. At a speed of 2 knots - which corresponds to around 3.7 kilometers per hour - such a mission can last up to 20 hours. For visual mapping of the shore areas, TAPS has two cameras attached to a mast, each pointing to starboard or port and whose fields of view do not overlap. Due to their high resolution, they allow a visual inspection of relevant infrastructure, such as quay walls, as well as 3D modelling of the shore area based on the recorded image data.

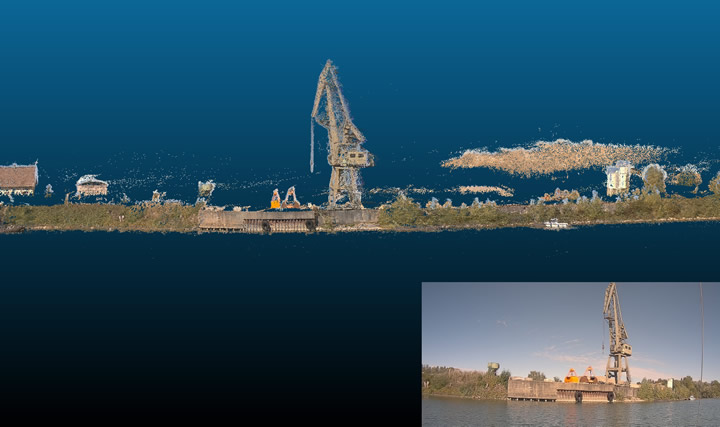

3D model of a surface structure

"We use an automated system for intelligent image capture. As soon as one or both cameras are focused on a predefined area of interest, image recording is started. The vehicle's own movement is also used to store only image data that is recorded from different angles and therefore offers added value in terms of content," explains Boitumelo Ruf, expert in photogrammetry in the Autonomous Robot Systems research group at Fraunhofer IOSB. GNSS (Global Navigation Satellite Systems, such as GPS) and IMU (Inertial Measurement Unit for position determination) data serve as the basis for determining the position and orientation of the TAPS platform. "When the images are captured, they are enriched with the current GNSS position data. The latter are required later for the assignment of precise coordinates," Ruf continues.

The watercraft autonomously maneuvers around a leaking inflatable boat.

After data acquisition, the recorded images are transmitted together with the GNSS data to a ground control station, where a photogrammetric reconstruction is carried out. Boitumelo Ruf describes the procedure in more detail: "Among other things, we use the COLMAP photogrammetric toolbox. It uses outstanding image features to first compare the input images, calculate their relative positions and create a true-to-life 3D model of the environment. We then use the tool to match the images pixel by pixel, i.e. we search for corresponding pixels and merge them exactly. The result is a dense 3D point cloud that is georeferenced using the GNSS positions, i.e. provided with the corresponding current coordinates." The 3D model can then be used for other tasks, such as visual inspections or bank monitoring.

Robust industrial cameras defy wind and weather

On the camera side, the Fraunhofer Institute relies on two uEye FA industrial cameras from IDS. The robust and resilient models with PoE are ideal for demanding environments. Camera housings, lens tubes and the screwable connectors meet the requirements of IP code IP65/67 and are thus optimally protected against dirt, dust and splash water.

The model used has the large-format 1.1" CMOS sensor IMX304 from Sony and delivers very clear, noise-free images with a resolution of 4096 x 3000 pixels. Thanks to its remarkable dynamic range and very high sensitivity, the global shutter sensor of the second pixel generation of the Pregius series is particularly suitable for metrology applications, among others.

The model used has the large-format 1.1" CMOS sensor IMX304 from Sony and delivers very clear, noise-free images with a resolution of 4096 x 3000 pixels. Thanks to its remarkable dynamic range and very high sensitivity, the global shutter sensor of the second pixel generation of the Pregius series is particularly suitable for metrology applications, among others.

It was precisely these characteristics that were decisive for the Fraunhofer IOSB's choice of camera. In addition to robustness and weather protection, important requirements for the cameras included a compact form factor and high image resolution to enable detailed visual inspections. The sensor should also offer a high dynamic range in order to capture images with a high level of detail in both sunny and shady areas. Integration via the standard GigE Vision interface enables the development and use of one driver for several systems with different cameras.

Outlook

The shortage of skilled labor is also a major issue in the surveying of waterways. Automated mapping of the waterways could not only reduce costs but also the time and, above all, the labor required. The aim of the TAPS project was to develop a prototype for this task and to demonstrate its potential in relevant scenarios. As a research organization, Fraunhofer typically develops technologies up to a level at which the functionality and suitability of the system have been proven. The next step is now cooperation with industrial partners. Dr Janko Petereit, head of the Autonomous Robot Systems research group at Fraunhofer IOSB, explains: "We are actively looking for partners to take this final step towards commercialization together. In view of the positive results of our initial tests and the increasing demand for accurate, up-to-date waterway maps, we expect strong demand for our technology in the coming years. The knowledge gained can be used in a variety of ways. Autonomous watercraft can be used to transport people and goods by sea or inland waterways. The excavation of waterways and the autonomous surveying of fairways are also conceivable. “

The project demonstrates the high potential of the interaction between robot systems and digital image processing. The charts could be reshuffled in the future, particularly with regard to visual environment detection and scene interpretation.

Camera

uEye FA - the most robust and resistant industrial camera

Model used: GV-5200FA

Camera family: uEye FA

Customer

The Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB aims to efficiently support people in making informed decisions, optimizing processes and intelligently controlling autonomous systems with its work in the three core competencies that give the institute its name. This involves the development of new types of vision systems, including the necessary laser light sources, the optimal use and networking of sensors and the processing of the resulting data streams.

Further information on TAPS >>

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

IDS Imaging Development Systems Inc.

World-class image processing and industrial cameras "Made in Germany". Machine vision systems from IDS are powerful and easy to use. IDS is a leading provider of area scan cameras with USB and GigE interfaces, 3D industrial cameras and industrial cameras with artificial intelligence. Industrial monitoring cameras with streaming and event recording complete the portfolio. One of IDS's key strengths is customized solutions. An experienced project team of hardware and software developers makes almost anything technically possible to meet individual specifications - from custom design and PCB electronics to specific connector configurations. Whether in an industrial or non-industrial setting: IDS cameras and sensors assist companies worldwide in optimizing processes, ensuring quality, driving research, conserving raw materials, and serving people. They provide reliability, efficiency and flexibility for your application.

Other Articles

2D cameras for positioning and inspecting ultra-fine wires in semiconductor production

Pallet by pallet - Intelligent robotic vision system destacks up to 800 objects per hour

Trained quickly, inspected swiftly - Handling and defect inspection of indexable inserts

More about IDS Imaging Development Systems Inc.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product