The higher the torque, the greater the ability to rotate heavy objects, overcome tough resistance or to transport objects vertically. Applications which rely on high torque can include hoists and cranes, as well as industrial mixing machines.

Understanding Torque and Speed in Electric Motors

Understanding Torque and Speed in Electric Motors

Article from | Parvalux by maxon

When selecting an electric motor for an application, regardless of project size or industry, two of the most critical performance factors to consider are torque and speed. These elements determine how well the motor can perform specific tasks, such as lifting heavy loads, running at high speeds, or providing precise control in an industrial setting.

The Importance of Torque

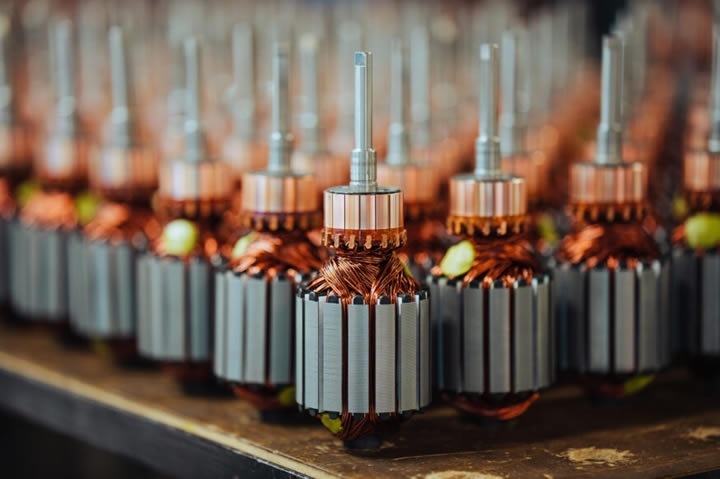

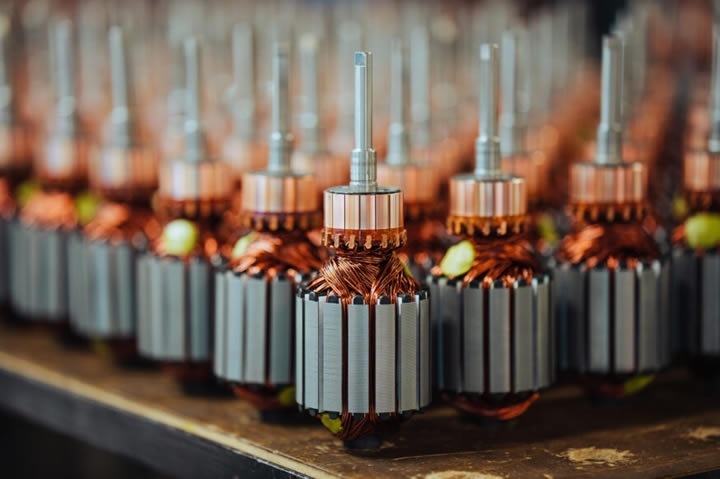

In essence torque is a measure of the rotational force produced by an electric motor and therefore the force available to rotate an object, such as a conveyor belt, fan, or machinery components.

The higher the torque, the greater the ability to rotate heavy objects, overcome tough resistance or to transport objects vertically. Applications which rely on high torque can include hoists and cranes, as well as industrial mixing machines.

The Need for Speed

The speed refers to how fast the motor’s output shaft rotates. High-speed motors rotate faster and are ideal for applications where rapid movement or high rotational velocity is required.

High speed motors can often be found in HVAC (heating, ventilation and air conditioning) systems or conveyor systems within the manufacturing industry which requires fast-paced activity.

The Relationship Between Speed and Torque

There is an inverse relationship between torque and speed in electric motors. As the speed increases the torque decreases, and vice versa. So, in the simplest terms, when the motor has a low speed it has a high torque, and when it has a fast speed it produces lower torque.

A motor with a low speed but high torque is suited for lifting or rotating heavy goods or where precise and powerful force is required. Such applications will include; conveyor belt systems which move heavy products across production lines; winches, hoists and cranes which need to move heavy objects carefully. Drilling equipment is also used to work through tough materials which require force and precision.

Alternatively, a high-speed motor with low torque is ideal for applications which don’t require heavy lifting such as: medical laboratory equipment like centrifuges and pumps which rely on fast rotation, but minimal power; food processing equipment, such as blenders and slicers; HVAC; and irrigation systems where moving liquid doesn’t encounter much resistance.

The Importance of Control

Getting the right combination of speed and torque is vital for the success of your project, as different applications require different combinations. There are two main ways of adjusting these combination ratios: changing gear ratios, and motor winding adjustments.

Geared Motors

Combining your electric motor with a gearbox can make adjusting torque and speed easier.

- High-Torque, Low-Speed Applications – Geared motors with high gear ratios are often used to increase torque whilst reducing speed.

- High-Speed, Low-Torque Applications – Motors with lower gear ratios are used to increase speed whilst reducing torque.

Partnering with Parvalux

Understanding the differences between torque and speed and their relationship in electric motors is essential for selecting the right motor for your application. Whether your focus is on lifting heavy loads with high torque or achieving rapid movement with high speed, there are various ways to adjust motor performance to meet these specific needs.

Therefore getting the right combination of speed and torque is vital to the success of your project and here at Parvalux we pride ourselves on our experience and knowledge of electric motors and we specialize in providing motors tailored to various applications.

We offer a wide range of motors including off the shelf, modular, and fully bespoke depending on your specific requirements.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

Multi-axis motion control drives pipe-based robots

Automate 2025 Q&A with maxon group

How Parvalux Is Helping to Develop the Next Generation of Conveyor Systems

More about maxon group

Featured Product