SUPPLIER SELECTION FOR CRITICAL MOTION CONTROL APPLICATIONS

The motion control sector is crowded with solutions for an array of applications across industry, and it is sometimes difficult for a non-motion control expert to navigate the plethora of information and data sheets that lay claim to describing the ideal customer solution. When looking at the area of ultra-precise (sub-micron to nanometer-levels of accuracy) the number of players is reduced, but it is probably fair to argue that the amount of information supporting claims of precision are even greater (and to a large extent more difficult to understand.)

It is undoubtedly the fact that this forest of information, claims, and counter-claims can be confusing for customers, and this confusion can lead to the purchase of motion control solutions which are either over-engineered and more expensive than some applications require, or more likely unable to achieve the required level of precision repeatably to satisfy the demands of manufacturers working in exacting industry niches.

This situation is unsatisfactory for customers and vendors alike, and there is a need for some degree of clarity that helps customers to partner with the best vendor for their specific applications and requirements.

At ALIO Industries, working at the nanometer-level of precision, a significant step towards providing this clarity was recently introduced as we launched our on-line product configurator. Through the configurator, customers can put in headline application requirements, and are then presented with viable solutions. So if users know the direction of motion required; the basic product type (i.e. linear motion, z-lift vertical stages etc.); application specific needs (i.e. smooth continuous movement, step and settle etc.); open center or closed; travel range; maximum weight of payload; level of bi-directional repeatability; and the environment the application is to be used in (ambient, cleanroom, or vacuum); the product configurator will display ALIO’s relevant options with each application requirement displayed graded best fit, good fit, or just fit. This is a major step forward for customers looking to specify motion control options.

But in addition to such tools, it is important that customers know what it is that they should ask of motion control suppliers before they are short-listed to avoid the waste of time and resource of first entering into lengthy consultation with a supplier that does not fit in with key criteria, and second — and most detrimental — actually investing in a motion control solution that is not optimal for the requirements of a specific application.

Bald statements about accuracy can on occasions obscure enormous differences between the capabilities of vendors in terms of repeatability, and motion control solutions being fit for purpose. Starting from the premise that if a good motion control solution is expensive, a bad one (with all this implies in terms of time delays and costs of re-investment in a suitable motion control solution) is REALLY expensive, in this article, I attempt to arm manufacturers with the questions that they need to ask to ensure that the motion control solution option chosen is right first time and up to the job. These questions should ideally focus on not just capabilities but also values.

QUESTION 1. WHAT DO YOU MEAN BY MOTION CONTROL?

This may seem like an odd question to ask a motion control technology provider, but it does actually get to the heart of the difference between some vendors. Most vendors sell off-the-shelf solutions and leave their customers to align them with their specific applications. In a way, this demotes motion control to a necessary evil, a link in a process chain that is expensive and complicated. But when your vendor provides truly cutting-edge sub-micron or nanometer-level accurate and repeatable motion control solutions, it elevates motion control from a necessary evil to an enabling technology. If a vendor provides the best-in-class, most accurate, and most repeatable motion control solutions on the market, they will be able to push the boundaries of what customers may see as possible, and will therefore promote the ability to manufacture innovative, bleeding-edge products that stimulate competitiveness. Try and assess your short-listed vendor’s view of motion control. Do they see obstacles and problems, or opportunities and solutions?

QUESTION 2. DOES YOUR COMPANY BUILD & ASSEMBLE ITS MOTION SYSTEMS, AND IF SO HOW IMPORTANT DO YOU THINK VERTICAL INTEGRATION IN THIS CONTEXT?

The range of applications for which precision motion control solutions are needed is vast, and in many instances off-the-shelf solutions are not the answer. To be able to customize motion control solutions, it is vital that your chosen vendor is in full control of every step of the production process as it is only through this intimate knowledge of the construction of stages that vendors will be able to adapt them optimally. When working in a world where sub-micron and nanometer-levels of accuracy are the norm, it is also preferable that motion control products are manufactured in one facility. Ask your vendor whether they have design, machining, metrology, manufacturing, and assembly under one roof. In other words, what steps of the manufacturing process are insourced or kept in-house to ensure consistently high quality while maintaining necessary flexibility. If the aspiration is to produce optimal end-use motion systems, that aspiration needs to be reflected in the manufacture of each component of the finished system. The cross collaboration between product development teams is important when trying to produce reliable and repeatable ultra-precise motion control solutions, and vertical integration is disproportionately important as the demands for accuracy move from micron-level to sub-micron and nanometer-level precision.

QUESTION 3. CAN YOU PROVIDE EVIDENCE OF INNOVATION IN THE MOTION CONTROL SOLUTIONS YOU PROVIDE?

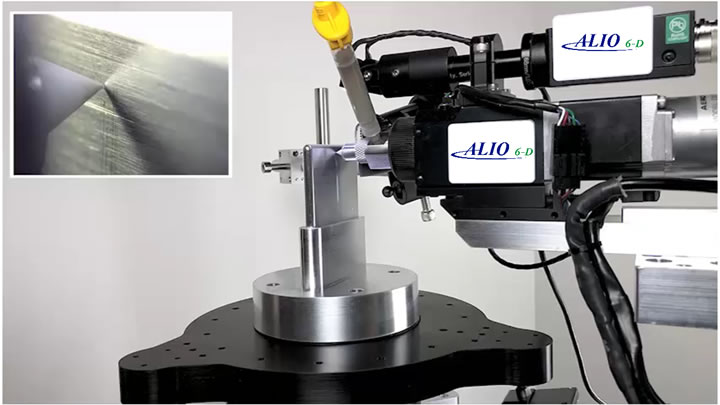

The sign of a cutting-edge motion control supplier, and one that will be able to fulfil your requirements with future-proof solutions, is evidence of innovative solutions that redefine the motion control market, where motion system developers think out of the box. Here you should be looking for signs of next-generation “blue ocean” technologies, not variations of legacy traditional motion control technologies. This is like the difference between vendors selling hexapods and a company like ALIO selling next-generation Hybrid Hexapods, which overcomes process limitations in traditional hexapods, and exhibits orders-of-magnitude improvements in precision, path performance, speed, stiffness, and larger work envelope. Nanometer-level repeatable motion control is achieved by pushing the envelope, not tweaking old technologies to squeeze out ever decreasing increases in accuracy. Check out your vendor’s portfolio of products, the customized solutions they have provided, and the level of innovation that is evident in creating new solutions and their ability to understand and apply their expertise to stimulate innovation in your application. Also, check out the warranty that your vendor is willing to extend. This is a sure-fire way of understanding the level or confidence they have in their own solutions.

QUESTION 4. CAN YOU PROVIDE EVIDENCE OF REPEATABLE TOLERANCE ATTAINMENT NOT JUST BEST TOLERANCE ATTAINMENT?

Pinning down motion control vendors over statements of precision can be a minefield. Ultimately, claims on sub-micron and nanometer-level precision is meaningless unless the precision is achieved repeatably. Vendors that may struggle to achieve repeatable precision in motion control may publish “typical specifications” and “guaranteed specifications”. Typical specifications will show what “could” be possible and are often more precise than the precision levels that can be guaranteed. This can be extremely confusing for customers. Aware of such issues, ALIO Industries, talks in terms of Point Precision referencing performance specifications to a point in space at the single digit micron or nanometer level, and NIST has now produced the ASME B5.64 standard “Methods for the Performance Evaluation of Single Axis Linear Positioning Systems” which advocates a new method for defining the precision of advanced motion control solutions similar to suggestions made by ALIO Industries moving away from conventional planar methodologies. It is important that customers interrogate precision claims diligently before a making motion control technology purchase in order to specify a solution that can repeatably achieve the levels of precision required.

QUESTION 5. CAN YOU DEMONSTRATE YOUR ABILITY TO CUSTOMIZE SOLUTIONS & PROVIDE EVIDENCE OF SIGNIFICANT SALES INTO VARIOUS RELEVANT INDUSTRY NICHES?

It is likely that your application will be best suited if vendors sell you motion control “solutions” not just “products”. The key is to be able to customize motion control solutions to specific customer applications in order to optimize outcomes. When working in the area of sub-micron and nanometer-level motion control, your chosen vendor should be able to demonstrate extensive experience working at these levels of precision, and should preferably be entirely focussed on ultra-precise solutions. A vendor should be able to prove its credentials and demonstrate that it has provided a significant number of best-in-class, efficient, and cost-effective sub-micron and nanometer-level motion control solutions for an array of different industry applications. Ask your chosen vendor for evidence. All claims made should be able to be substantiated.

QUESTION 6. CAN YOU EXPLAIN THE RELATIONSHIP YOU HAVE WITH CUSTOMERS BEYOND THE SALE OF A MOTION CONTROL SYSTEM?

For success when the requirement is for sub-micron and nanometer-levels of repeatable motion control, there is much to be said to work with a vendor that places an emphasis on strategic partnership in product development. This will increase your confidence in achieving your challenging motion control and manufacturing goals in a timely, efficient, and cost-effective way. Key is early-stage engagement with your chosen vendor, and a willingness for the vendor to truly become embedded in the development of your end-use products and associated motion control solutions. Wherever possible, standard off-the shelf solutions should be found that fulfil the requirements of customer applications, but your chosen vendor should also be able to customize solutions when necessary to fulfil special application requirements. Seek evidence that your short-listed vendor sees the importance of full partnership, collaboration, and engagement as a way of providing quality, speedy, and cost-effective outcomes.

QUESTION 7. CAN YOU PROVIDE ME WITH SOME INSIGHT INTO THE EXPERIENCE AND EXPERTISE OF YOUR TEAM?

It is surely true to say that the key driver behind the competencies of any company is its team, so you need to drill into the experience and technical know-how. When your requirement is for sub-micron and nanometer-level motion control, you need to make sure that your vendor has a team with a dedicated focus that will translate into innovative and cutting-edge motion control solutions. Much of this is about the culture you will see in a vendor company. Assess whether you detect a “can do” attitude and whether your vendor seems to nurture a collaborative environment. But above all see if you can feel a passion running through your vendor’s team. If the passion is there, honesty and integrity will often follow, and with that will come trust. And it is ultimately trust that you need to bottom out when choosing a vendor. You need to trust that the motion control solution that you buy fits your requirements, and this is comes down to the team ethos that runs through all inter-connected departments in the company.

Featured Product