Miniature electric motors help robots get a grip

Grippers are essential for robots engaged in pick-and-place applications. These electromechanical ‘hands’ allow objects to be grasped, manipulated and released, facilitating fast and precise interactions for low-mix, high-volume industrial processes. For the past three decades, pneumatic designs have been preferred by automation specialists - but this is changing. Electric grippers are proving a more modern solution, providing benefits in terms of efficiency, cost optimization, and space saving. At the heart of this advancement are miniature electric motors.

Pick-and-place robots have become a staple in assembly, manufacturing, packaging and material handling applications, where repetitive tasks must be carried out with high speed and minimal errors. Able to operate in confined spaces, handle a wide variety of objects and conduct multiple tasks – these programmable robots have revolutionized many industries.

However, increasing demands upon robots have exposed the limitations of using pneumatic grippers in these applications. Operators require robots that offer more precise control of grasped objects, increased intelligence and additional functionality to support complex, modern processes. Robots must also be compact to maximize productivity in existing or limited floorspace. On top of this, end users want to reduce maintenance costs and energy usage to lower operating expenditure (OPEX). In all scenarios, electric grippers, powered by miniature electric motors, supersede pneumatic designs.

All under control

Control and grip force are arguably the most important performance parameters for grippers, and miniature electric motors excel in both regards. Precise control of position, speed and torque can be achieved more effectively than with other types of actuation systems – making electric grippers ideal for complex manufacturing.

In terms of grip force, this can be modulated by controlling a motor’s current or voltage. As a result, the gripper can delicately handle fragile objects, like electronics, or hold heavier, more robust loads, with a tighter grasp. Electric grippers offer the advanced control and grip options required to support a myriad of modern pick-and-place applications.

Do it again, and do it quickly

One of the inherent benefits of using robots is increased process speed. Electric grippers compound this advantage thanks to motors that reach high speeds with incredibly quick acceleration. Rapidly opening and closing the grippers allows the pick, place and release mechanism to be completed quickly – reducing cycle times and improving productivity for automated systems. The lower the inertia of a specified gripper motor, the bigger the benefits.

However, fast cycle times must be backed by repeatability. Thankfully, electric motors can perform motions over and over again with high accuracy. In applications where consistent gripping and releasing actions are required, like bin picking, this is crucial.

Keeping things compact

The problem with a pneumatic gripper system is that it requires complex air supply systems like compressors, filters, regulators, and valves. This increases the footprint of a robot which, considering the production manager’s goal to achieve more in less space, is undesirable.

Conversely, miniature electric motors are designed to offer big power in a small package. Available space on a gripper is limited, but torque dense electric motors maximize it by offering easy integration without the need for bulky sub-systems. This can save space on the production line for operators and offers original equipment manufacturers (OEMs) the chance to downsize robot designs.

Flexibility in application

End users of pick-and-place robots need a wide range of control and integration options to ensure suitability for varied applications. Unlike pneumatic designs, electric grippers can be easily guided by and interfaced with different control systems, whether that is programmable logic controllers (PLCs), microcontrollers, or computers. This ensures a wide range of implementation options for custom automation setups.

Furthermore, motor feedback can be used for grip programming instead of timers, which combined with sensors, can create more efficient programs and support more complex processes.

Controlling cost

Electric grippers are energy efficient by design, especially when utilizing brushless DC (BLDC) motors. By converting electricity into mechanical energy with minimal losses, these motors have reduced power demand, which translates into lower energy costs. Across a facility, this efficiency gain can add up to a significant saving.

Compared to pneumatic systems, electric grippers save money in terms of maintenance too. A simplified system without additional subsystems, electric grippers are easier to maintain. Not having to contend with the additional complexities of a pneumatic system makes servicing faster and more cost effective. By using electric grippers, operators can expect a reduction in OPEX.

Picking motors for electric grippers

With the benefits of electric grippers demonstrated, the challenge for machine builders is which motor to choose for these systems?

Ultimately, BLDC motors are ideal for gripper applications, providing excellent control of high speeds and torques in a reliable, compact package. This makes them highly suitable for rapid and accurate gripping movements.

For those looking for this dynamism in an even smaller package, flat BLDC motors can be utilized. Specialized for use in limited space, flat BLDC motors are a pancake-shaped design with a flat profile, allowing easy integration into compact gripper systems.

With these two designs, OEMs and end users have a ready-made solution to make the transition from pneumatic to electric grippers.

Getting to grips with specification

Every robot, gripper system and pick-and-place process is different, which is why expert support from companies such as Portescap is invaluable. Portescap’s range of Brushless Slotless motors, including Ultra EC™, and Flat BLDC motors, offers the performance attributes required for electric grippers.

Multiple winding and gearbox options allow refinement of speed and torque, while hall sensors and encoders help ensure accurate, intelligent control and precise positioning. Special materials enable motors to withstand shock, high duty cycles and a range of temperatures. Furthermore, working closely with customers, Portescap can integrate miniature motors into devices, saving space and weight in robot designs.

With this personalized engineering support, end users and OEMs can pick a miniature motor solution that places them at the forefront of electric gripper performance.

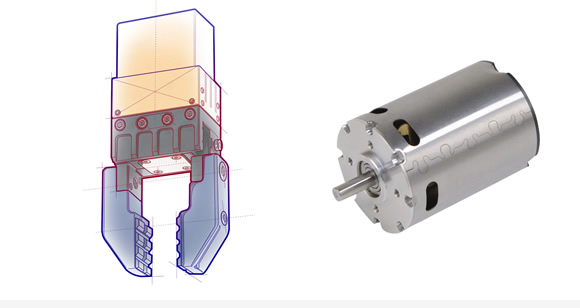

Image 1: Precise control of position, speed and torque can be achieved more effectively than with other types of actuation systems – making electric grippers ideal for complex manufacturing.

Image 2: Portescap’s range of Brushless Slotless motors, including Ultra EC™, and Flat BLDC motors, offers the performance attributes required for electric grippers.

Portescap offers the broadest miniature and specialty motor products in the industry, encompassing coreless brush DC, brushless DC, stepper can stack, gearheads, digital linear actuators, and disc magnet technologies. Portescap products have been serving diverse motion control needs in wide spectrum of medical and industrial applications, lifescience, instrumentation, automation, aerospace and commercial applications, for more than 70 years.

Portescap has manufacturing centers in the United States and India, and utilizes a global product development network with research and development centers in the United States, China, India and Switzerland.

For more information, visit www.portescap.com

Featured Product