Developing robotic solutions: partnering for success in micro-motion control

The spread of robotic technology across various sectors continues to advance in line with technological development. Notably, the proliferation of robotics is enhancing efficiency, safety, and productivity in the manufacturing sector including industrial automation applications. Yet, robots are also enhancing lives in medical settings, such as improving precision in surgery, which can improve the patient outcome and speed up recovery.

This diversity in applications means that, dependent on the robot’s purpose, OEMs have an array of considerations to make in design. Central to all robots, whatever the application, is the motion control technology – motors, gears, and feedback devices - that drives the limbs, joints, and end effectors. The ultimate requirements of the robot have significant implications on the design of the motion system.

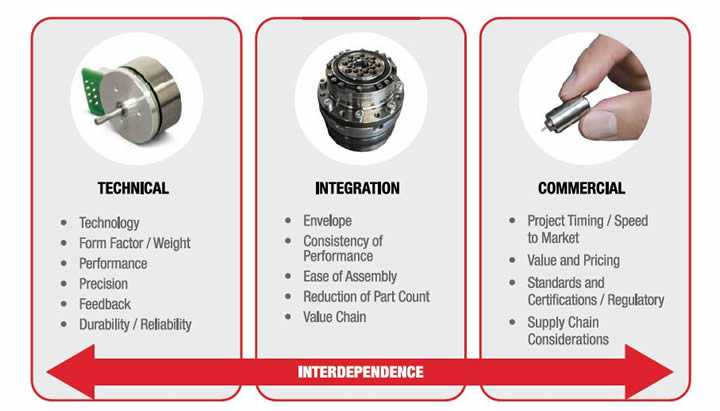

Not only does motion design require an assessment of the technology that can solve the challenge most efficiently, but it must also satisfy commercial needs for the OEM. This means the motion system must optimally integrate with the overall robot design, while ensuring ease of assembly and regulatory compliance.

Challenges of motion control development

Calculating the working points is a primary step for engineers when designing electromechanical solutions. Determining torque, radial, and axial loads are critical factors that the motion system must be able to achieve. Yet alongside these fundamental needs, the kinematic demands of a robot are vital. This includes the motion profile of the device, and how smooth, responsive, and precise this movement should be – all factors that result from the performance of the motion control system.

Crucial to the dynamic performance of a robot is miniaturization. A compact, lightweight system has low inertia that enables responsiveness, and low mass also optimizes efficiency. Moreover, a micro motion system is essential because of demands on the overall design footprint. To suit the characteristics of many robots and the environments in which they operate, these motion systems must fit within limited physical space - and integrate smoothly with other components. Yet in achieving this, the motion system must still meet the required operating points and desired motion profile.

In addition to these needs, reliability is also paramount. Maintenance challenges or failure in an industrial automation setting can mean downtime, but in a medical setting reliability can impact human safety. Miniaturization of the motion system adds complexity considering the demands of thermal management, and engineers must also take into account component compatibility, working points including overload and continuous operation, along with other potential failure modes. The environment of operation is also significant to reliability, considering heat (or cold), and the potential for ingress, so the motion system’s design must ensure adequate protection.

For robot drive system development, technical performance, design integration, and commercial needs are interdependent.

From concept to manufacture

Only after investing considerable time and effort into research surrounding these aspects, and a concept has been developed, can a design be created to confirm the ease of manufacturing. Yet the progression from the conceptual design of a motion system to one that can be achieved on a manufacturing scale is significant. The need to revise or change technical attributes and previously selected components, or even materials selection, can introduce roadblocks that add significant time to project development.

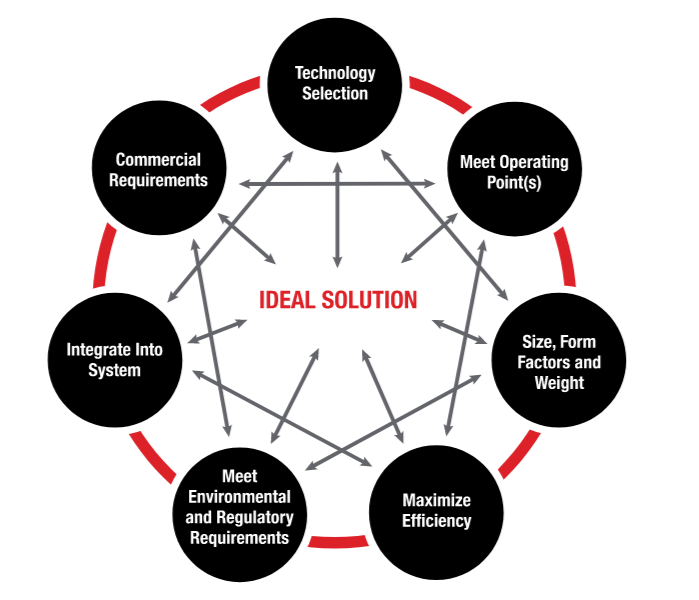

To reduce the challenge of moving from prototype to full production, prioritization of motion system design requirements at the earliest stage is crucial. This ranges from the fundamental level of balancing torque output with thermal management and footprint requirements, to long-term reliability considerations involving choice of motor technology and material selection. What’s more, all these considerations must be compatible with commercial imperatives.

This balancing act can be less burdensome with the support of an experienced partner who is well versed in addressing these challenges. Moreover, a motion expert can point towards critical factors, previously unconsidered, that could impact the delivery of the project at a later timescale – potentially reducing significant time and cost that could otherwise be added in rework.

Finding the ideal robotic motion solution is a balance of interrelated considerations.

Involving motion engineering expertise

By relying on motion control experts that offer diverse, application-specific solutions, combined with an understanding of manufacturability methods and awareness of commercial challenges, robot developers can achieve the optimum path for motion development. This can also involve the choice between Commercial-Off-The-Shelf (COTS) solutions and customization. In addition, a significant benefit of working with a dedicated motion expert is the technical support available throughout the entire development process to ensure maximum reliability and integration.

Taking into account the array of options in robotic motion development, it is essential to think beyond the parameters of speed and torque. Not only will the motion system directly impact the robot’s performance, but it will have strong implications for its long-term reliability.

Turning the optimum concept into a manufactured reality is also where expertise can be essential. By partnering with a dedicated motion engineering team, a viable commercial solution, developed to a much closer timescale, is more likely to be achieved. Ideally, this relationship between robot OEM and motion developer should start as early as possible in the project to optimize the outcome.

About Portescap

Portescap offers the broadest miniature and specialty motor products in the industry, encompassing coreless brush DC, brushless DC, stepper can stack, gearheads, digital linear actuators, and disc magnet technologies. Portescap products have been serving diverse motion control needs in wide spectrum of medical and industrial applications, lifescience, instrumentation, automation, aerospace and commercial applications, for more than 70 years.

For more information,visit www.portescap.com

Featured Product