Joint actuators: The fundamental component for humanoid robots’ power and dexterity

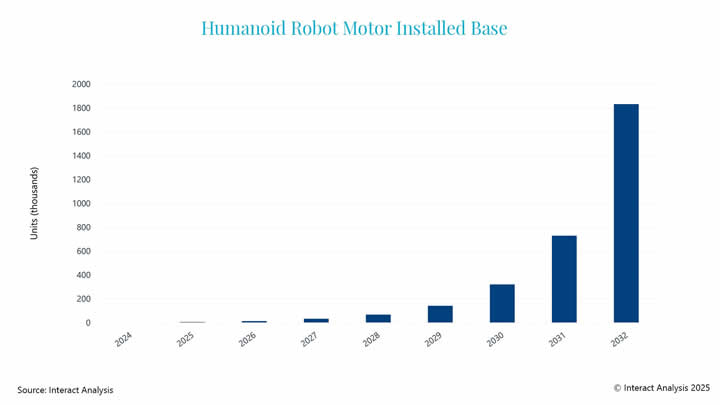

While there are several barriers that will constrain growth of the humanoid robots market in the short to mid-term (see our latest findings and market projection for Humanoids in this published insight: Humanoid Robots: Large opportunity but limited uptake in the short-to-mid-term), the number of joints in each robot still presents a large opportunity for component vendors, highlighted in the chart below.

High demand for actuators is expected to drive strong humanoid robot motors market growth

Among the many components of humanoid robots, joint actuators undoubtedly play a crucial role, particularly in several key areas:

- Firstly, the large quantity of joint actuators required for humanoid robots results in a high proportion of bill of materials (BOM) cost. A full-sized humanoid robot typically has dozens of degrees of freedom, and each degree of freedom requires a joint actuator. For example, Tesla’s Optimus humanoid robot has more than 28 rotary and linear actuators, while its dexterous hand may contain even more miniature actuators. This enormous demand per machine makes joint actuators a major component of the hardware cost structure for humanoid robots. According to our recent research report Humanoid Robots – 2025, joint actuators typically account for >30% of the overall BOM cost in a high-configuration humanoid robot (including 5-fingered dexterous hands, high-computing chips, high-end sensors). The share can be more than 50% in some basic versions without dexterous hands and high-end sensors. This means the cost and supply capacity of joint actuators directly affect the cost efficiency and scale-up feasibility of humanoid robots.

- Secondly, joints are core components of robotic locomotion, closely related to the stability and safety of robots during operation. The performance of joint actuators directly determines the motion smoothness, precision control, and dynamic response capability of robots. High-performance joints are preconditions in preventing jitter, instability, or even falls. The reliability and safety of joints are crucial, as the failure of any single joint could lead to overall functional damage or even safety incidents.

- At the same time, different joint positions have varying requirements for size and performance. Different joints of humanoid robots (such as shoulders, elbows, wrists, hips, knees, ankles, etc.) have different requirements for range of motion, load capacity, precision, response speed, and more. For example, leg joints responsible for supporting body weight and large-amplitude movements need to output greater torque and have higher rigidity, while arm and wrist joints responsible for fine operations have higher requirements for lightweight design, compactness, and positioning accuracy. This differentiated demand makes the design and selection of joint actuators extremely challenging. Customized or serialized development is required for different positions, resulting in high research and manufacturing costs in the absence of scaled demand.

Technical requirements of humanoid joint actuators

Although there are structural similarities between humanoid robot joints and collaborative robot joints, there are still many differentiated requirements that pose higher performance demands.

Among these, lightweight and miniaturization are primary goals and, as a result, high-torque density actuators are preferred. Lightweight joints help cut system weight, enhance flexibility, and reduce the energy consumption of joints, thereby improving battery life. The anthropomorphic requirements arising from high adaptability to human world mean that humanoid robot joints need human-like dimensions. For example humanoid robots are expected to perfectly fit in the space designed for a human and be capable to use tools designed for human. Therefore, humanoid robot joints require highly compact designs that tightly integrate relevant components such as motors, gearboxes, drives, encoders, and even sensors into a single module.

Low energy consumption and low temperature rise are critical, especially for humanoid robots with numerous joints but limited battery space. The energy utilization and heat dissipation capabilities of joints directly affect their endurance and overall performance. Additionally, humanoid robots should be able to react in real-time within complex changeable environments, which increases the requirements for joint dynamic control and adaptability. This poses higher challenges for joints’ peak torque and control algorithms.

Joint peak torque of some humanoid robot models

Due to these differentiated technical requirements, in the early stages of development there was a relative lack of standardized, low-cost joint products that fully adapt to humanoid robots on the market. Instead, many humanoid robot vendors chose to invest in designing and even manufacturing joint actuators themselves to meet the specific needs of their products.

However, with the rise of the humanoid robot industry, over the past 12 months more and more robot component manufacturers have begun to actively create high-performance, cost-effective integrated joint products. These companies are striving to seize opportunities and become Tier 1 core suppliers in the humanoid robot industry supply chain. Many vendors specialized in motion control and drive technology – like Kollmorgen, Archimedes Drive, and TQ-System – have released their actuation solution for humanoids. In China, there are dozens of component vendors that have introduced off-the-shelf, integrated joint products for humanoids, including companies like TC Drive, Realman, and Kinco. This trend is expected to alleviate capacity constraints and the high cost of joint modules in the coming years, accelerating development of the industry.

Hardware technology continues to evolve during market infancy

Currently, hardware technology for humanoid robots is still iterating, with a wide variety of innovative solutions emerging. One reason behind this is that the downstream market and application scenarios for humanoid robots are still in the early proof-of-concept (POC) stage. Unlike the traditional industrial robots market, where mature applications have been developed, humanoid robots have enormous potential as a general-purpose automation platform. However, determining which specific scenarios will see them create significant productive value autonomously, and achieving efficient, reliable, scaled deployment still requires further exploration and validation.

This situation has created some uncertainty in the selection of hardware technologies. In joint design, although most manufacturers have reached a consensus on using harmonic modules for upper limb joints, there are still different technical solutions in the market. These include cycloidal actuators or quasi-direct drive solutions with extremely low gear ratios. For lower limb joints, harmonic, planetary, and RV rotary actuators and linear actuators based on screws all have corresponding manufacturers positioning themselves to lead the market. In terms of perception, although there appears to be consensus around multi-sensor fusion, identifying which specific sensor combinations to adopt and how to optimize fusion algorithms to adapt to different environments and tasks is still to be determined.

The diversity and rapid iteration of hardware technology routes reflect the innovative vitality of the industry on one hand, while on the other hand companies both upstream and downstream of the industry supply chain need to prepare for multiple possibilities and invest more resources in R&D and real-world validation. Which technology will eventually become mainstream largely depends on which specific scenarios can be successfully unlocked and scaled in the future: If humanoid robots achieve breakthroughs in the consumer sector first, then requirements for safety, low noise, low cost, and human-machine interaction friendliness will be higher. However, if they are widely applied in the industrial sector, then load capacity, operational efficiency and accuracy, and long-term reliability may be valued more highly. Therefore, hardware still needs more commercial deployment cases for validation and iteration to reach technical consensus and form industry standards. This will be crucial for large-scale adoption growth of humanoid technology.

To learn more about Interact Analysis Humanoid Robots – 2025 report, current market vendors and our detailed market projections, reach out directly to marco.wang@interactanalysis.com

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product