New Study Shows U.S. is World Leader in Robotics Automation - With $732 Billion of Robots

A new study from Redwood Software and the Centre for Economic and Business Research (CEBR) finds that the U.S. is the world leader in robotics automation investment, with an estimated robotics stock of $732 billion* - larger than the economy of Switzerland, which stood at $446 billion* in 2015.�

U.S. investment in robotics was $86 billion in 2015, up from less than $40 billion in 2009, when investment hit a low following the financial crisis, and more than 15 times higher than the OECD average. Between 2011 and 2015, U.S. investments in robotics rose 30%.�

"The U.S. is the world leader in robotics investment, and spending has recovered quickly since the financial crisis in 2009," said David Whitaker, Managing Economist at CEBR. "The sheer size of the economy and its large base of production in the automotive and electronic sectors make it a natural candidate for increased automation."� � � Full Press Release:

Robotics-focused ETFs see big gains, Trump could hasten trend

Ryan Vlastelica for MarketWatch: If robots are taking jobs, should you invest in the robot makers?

That’s the argument behind a pair of outperforming exchange-traded funds that track the robotics industry, which could continue seeing strong growth as more positions get automated by machines or algorithms.

In a Jan. 23 note, UBS named automation and robotics as one of the two areas of technological innovation that would drive productivity over the coming decade, along with the digital data industry.

“Both have the potential to profoundly transform the structure of our economy, disrupt existing business models, but also create substantial growth opportunities for those well-positioned to participate,” the firm wrote, singling out the ROBO Global Robotics & Automation Index ETF ROBO, +0.59% as a fund that would benefit from this trend, with the investment time horizon of a decade. Cont'd...

Chrysalix partners with Dutch RoboValley on €100 million robotics fund

Terry Dawes for Cantech Letter: Vancouver-based Chrysalix Venture Capital has announced a €100 million fund aimed at driving the global robotics revolution, in partnership withRoboValley, a centre for robotics commercialization based at the Delft University of Technology in the Netherlands.

The RoboValley Fund is Chrysalix’s first robotics fund, and will concentrate on disbursing seed and Series A rounds of funding to early-stage companies developing component technology, intelligent software, and other breakthrough robotics technologies.

“Robotics is predicted to be the next big step in the digital revolution having an unprecedented impact on the way that we live, and provides an answer to some of the grand challenges of the 21st Century,” said RoboValley managing director Arie van den Ende. “Together with Chrysalix long-standing expertise in commercializing early stage industrial innovations, the RoboValley Fund will bring much needed capital and accelerated paths to market for our most promising next generation robotics technologies.” Cont'd...

February Was Another Good Month For Robotic Investments

February was another big month for investments in robotic startup companies. 3D Robotics, Flyability, Fetch Robotics, EHang and many others.

Records 16 to 19 of 19

Featured Product

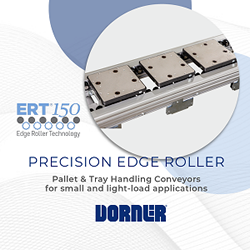

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.