AGV Navigation: What Are the Possibilities?

Various technologies are available on the market for bringing an automated guided vehicle (AGV) to its destination. Let us first of all say: many roads lead to Rome. There is no right way and no wrong way.

Streamlining Operations: Automotive Robotic Automation and Fork Truck Free Initiatives

Because of the very complex nature of automotive manufacturing AGV vehicles on the plant floor must feature a wide range of standard modules that are configurable to meet automotive customers' automation needs.

Traffic Control Software Redefines Value Proposition of Mobile Robots

The flexibility and easy integration of AGVs with a Fleet Control System, coupled with a minimally invasive installation, mobile robot systems can provide a rapid return on investment and become a substantial contributor to reduced operating expenses.

Talking IMTS with MiR Robots

We will showcase our latest autonomous mobile robot, the MiR500 which will have its American launch at IMTS. MiR500 is designed to automate the transportation of pallets and heavy loads across industries.

BrainOS for Commercial Robotic Navigation

For commercial robotics-where hitting a wall or a person with an 800-pound machine would be catastrophic-being confident that the robot is safe, secure, and well supported is critical.

Greater Demand for Automation and Technological Advancements to Boost the Warehouse Robotics Market

The warehouse robotics market is growing owing to the increased demand for automation, high competition in the e-commerce industry, and the advancement in technology.

Sprint Tests Robot EV Chargers In New York to Lower CO2 Emissions

Intelligent robots - to be powered by Sprint IoT and 5G - move autonomously to charge electric buses, cars and industrial vehicles

How Sensors are Moving Materials Handling Towards Safe Automation

Affordable, highly accurate and extremely reliable sensing systems and controls are fueling the rise of AGV solutions for a wide range of material handling applications in warehouses, factories and industrial facilities.

Automation of Internal Transportation

What Every Business Owner Needs to Know About the Technology Behind Autonomous Mobile Robots

The changing landscape of mobility as seen at Automate and ProMat

Retailers and logistics companies have been opening facilities at a record pace and in this fast-paced world, warehousing and logistics managers are looking for robotics solutions to remain competitive.

18 Questions to Ask Your AGV (Automated Guided Vehicle) Vendor: Part 1

You need an AGV solution that will grow with your company, adapting to your changing industry and taking on the challenges you face as your business grows.

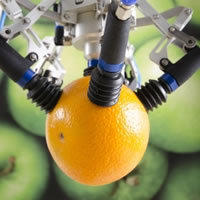

Robot Can Pick and Sort Fruit

A robotics breakthrough by product design and development firm Cambridge Consultants is set to boost productivity across the food chain – from the field to the warehouse. It paves the way for robots to take on complex picking and sorting tasks involving irregular organic items – sorting fruit and vegetables, for example, or locating and removing specific weeds among crops in a field.

“Traditional robots struggle when it comes to adapting to deal with uncertainty,” said Chris Roberts, head of industrial robotics at Cambridge Consultants. “Our innovative blend of existing technologies and novel signal processing techniques has resulted in a radical new system design that is poised to disrupt the industry.”

Advances in farming robotics could address shortage in agricultural workers

By Steve Brachmann for IPWatchDog: More and more, the agricultural world is looking towards the mechanization of labor processes through robotics as a way of potentially increasing their productivity. Robotics was identified as a sector of investment growth in agricultural tech by an April 2014 white paper on agriculture technologies published by the entrepreneurship and education non-profit Kauffman Foundation. Robotics is a regular focus of ours here on IPWatchdog, most recently visited in our coverage of the incredible advancements in walking and jumping robotics pioneered by Boston Dynamics, a Google Inc. (NASDAQ:GOOG) subsidiary. With American farmers already heavily involved in the regulatory conversation involving the commercial use of unmanned aerial vehicles (UAVs), or drones, we thought that it would be interesting to delve into the world of farming robotics and see the recent advances in that particular field.

It’s important to understand first that the robotics being developed for commercial use on farms won’t be stand-alone humanoid units ranging through fields to pick crops. Any piece of hardware implementing an algorithm which automates some of the manual work of farming falls under this heading. One good example of this is the LettuceBot, a precision thinning technology which works to visually characterize plants in a lettuce row, identify which plants to keep and eliminating unwanted plants to optimize yield. The unit doesn’t move by itself but is guided along by a tractor instead. The technology has been developed by Blue River Technology of Sunnyvale, CA, a company which has attracted $13 million in investment between 2011 and 2014 to commercialize this product. The LettuceBot’s creators hope toprovide the technology as a third-party service to farm owners before manufacturing the unit for commercial sale. Cont'd...

Hawk Aerial Introduces the CropHawk350 Solution for Agricultural Industry

Solution includes options for drone purchase, periodic crop monitoring and reporting

Robots at ProMat to Feature Indian AGVs for the First Time

Hi-Tech Robotic Systemz is making its North American debut at ProMat 2015 (booth #5521) in Chicago, IL, with a focus on automating e-commerce fulfillment centers.

Records 31 to 45 of 45

Featured Product

ATI Industrial Automation - MC-50 Manual Tool Changer

With intuitive and ergonomic lever operation, the patent-pending MC-50 Manual Robot Tool Changer provides a simple solution for quickly changing robotic end-of-arm tooling by hand. This compact and robust Tool Changer is designed for applications on collaborative robots that support payloads up to 25 kg and small industrial robots supporting payloads up to 10 kg. Featuring an ISO 50 mm mounting interface on the Master-side and Tool-side, the low-profile MC-50 mounts directly to most cobots and seamlessly integrates with many common cobot marketplace grippers and end-effectors.

.jpg)

.png)