Robots Double Worldwide by 2020 – IFR Survey

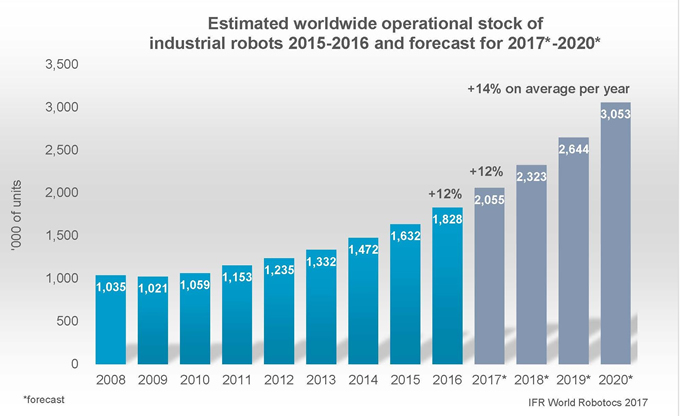

Nearly 70 percent of employees believe that robotics and automation offer the opportunity to qualify for higher skilled work. This is the result of a worldwide automatica survey of 7,000 employees in seven countries. The technological change calls for targeted training and further education for employees. More than 3 million industrial robots will be in use in factories around the world by 2020. This means that the operational stock will more than double within seven years (2014-2020).

According to the International Federation of Robotics, more than 3 million industrial robots will be in use in factories around the world by 2020. This means that the operational stock will more than double within seven years (2014-2020).

„IT like robotics process automation is by far the biggest contributor in transforming people’s jobs,” comments Junji Tsuda, president of the International Federation of Robotics. “Companies and governments must collaborate to ensure workers have the skills that the technological change requires.”

Singapore invests in SkillsFuture initiative

As far as training is concerned, Singapore is one of the most advanced countries with its SkillsFuture initiative. Employers in the city-state are asked to spell out the changes, industry by industry, that they expect to happen over the next three to five years, and to identify the skills they will need. Their answers are used to create “industry transformation maps” designed to guide individuals on where to head.

Since January 2016 every Singaporean above the age of 25 has been given $345 credit that can be freely used to pay for any training courses provided by 500 approved providers, including universities and MOOCs.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product