The Future of Machining: Key Trends and Innovations

AI and robotics are seen to deeply disturb specialized industry sectors, bringing beneficial pioneering modernizations in machining, industrial manufacturing and machine shops. Elitsa Krumova explores the future of machining in more depth on behalf of DELMIA.

Sustainable Industry Repair using RoboDK

The purpose of the project was to improve laser welding procedures and determine if sustainable gear repair was possible using robot toolpath programming, digital twin, simulation, and post-processing.

ABA Corp Implements Six Robots to Run Their CNC Machines in Their High Mix Production

The job shop manages small to large production run orders. Each cobot picks up parts from a bench, loads and unloads them from a CNC machine tool and places them in a box.

Ideal Spindles for High-Speed Robotic Milling of Plastics and Composites

One application for which robot arms are well suited is using a kind of deburring tool as a cutting instrument when working with relatively soft materials like plastics and composites.

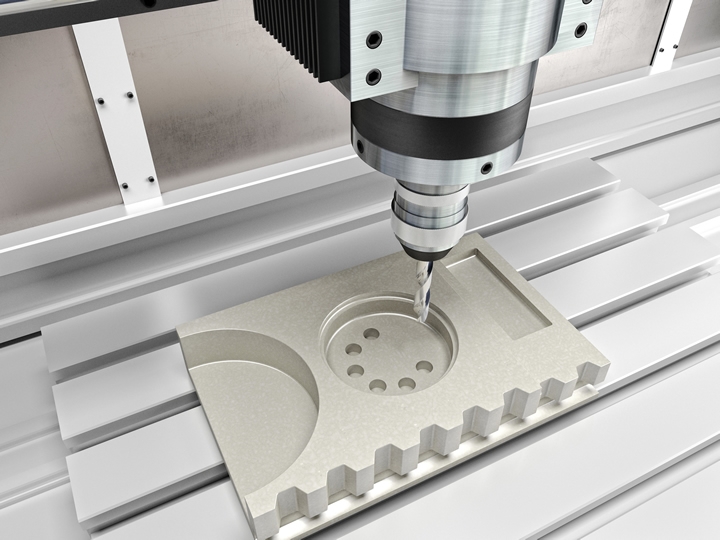

Automated Support Removal & Finishing for Metal AM - Robots vs CNC

This article will address the transition to automated support removal (and finishing) solutions and consider the advantages and disadvantages of using CNC systems versus the versatility and reliability of robots.

Automated Loading and Unloading of CNC Machines

The camera control, which gives the robot the flexibility for an infinite variety of parts, and the EasyControl graphical user interface with its easy-to-understand input screens that allow users to automate without any robot knowledge.

Variance and Volume Advantageously Combined One of a Kind in Series

Up until now, users in the metal and plastics processing industries often faced a difficult choice: with CNC lathes and milling machines, one opted either for the largest possible variance or for large volumes, i.e., high quantities.

Robotic Plasma Cutting in a 3D World

ARC Specialties designed and built a turnkey solution for 3D robotic plasma cutting with the help of essential offline programming tools. With the right partners by your side, no challenge is too steep.

Oasis - Engineering Success With People and Automation

Looking at robots I wanted something adaptable, flexible and quick to set up. We could have gone down the route of engineering our own solution to hold the parts, but this was an off the shelf unit interfaced to our machine with an automatic door, and it just does it all.

CNC Vs Robot

What are the differences between these two CNC and robotics systems? What are their characteristics and how do you determine which one is best suited to the needs of your industry?

Precision CNC Machining Company, Protomatic, Named "Top Shop"

CNC machining company, Protomatic, was recognized as one of 4 "Top Shops" by Modern Machine Shop magazine.

Diversified Machine Systems and Partner, Fagor Automation, Announce New Developments in Powerful CNC Programming Tools

Strategic partner of Diversified Machine Systems, Fagor Automation, announces new features and technology developments to the Fagor 8065 CNC control system.

CUSTOMIZED CNC UPGRADE SIMPLIFIES RAILCAR AXLE GRINDING

* novel task-oriented HMI simplifies control of plunge grinding operations

CNC Software, Inc. Partners with Edge Factor to Bring Free Multimedia Package and Materials to Manufacturers for Manufacturing Day Events

Manufacturing Day 2015, scheduled for October 2, 2015-the fourth annual industry grassroots event that is celebrated across North America and being promoted as "MFG Day."

The Crowning Conclusion: Universal Robots Saves 9 Hours of Production Time at Glidewell Laboratories

Having a UR5 robot tend four CNC machines milling dental crowns optimizes a substantial part of the production cycle at Glidewell Laboratories in Newport Beach, California.

Records 1 to 15 of 18

Featured Product

Discover how human-robot collaboration can take flexibility to new heights!

Humans and robots can now share tasks - and this new partnership is on the verge of revolutionizing the production line. Today's drivers like data-driven services, decreasing product lifetimes and the need for product differentiation are putting flexibility paramount, and no technology is better suited to meet these needs than the Omron TM Series Collaborative Robot. With force feedback, collision detection technology and an intuitive, hand-guided teaching mechanism, the TM Series cobot is designed to work in immediate proximity to a human worker and is easier than ever to train on new tasks.