Beyond Protection: How Advanced Sealing Solutions Are Enhancing Robotic Performance

Sealing technology plays a decisive role in ensuring performance stability, reducing friction, and protecting components from environmental influences. High-performance seals are essential for extending the life of robotic joints, actuators, and automated systems.

ANYbotics ANYmal robot is addressing key challenges in Industrial Robotics

The ANYmal robot addresses key challenges in industrial operations by offering autonomous, highly mobile inspection capabilities in complex and hazardous environments. Its four-legged design enables navigation through uneven terrains, stairs, and confined spaces.

Stretch and Spot: Increasing Operational Efficiency and Making Warehouse Work Safer

Stretch currently unloads boxes autonomously at the Hermes Fulfillment center, while Spot supports predictive maintenance by inspecting fire exits and structural changes and detecting air and gas leaks.

Robot Recovery - Flood Damage

No matter what caused the flooding there will be damage to equipment in your facility. With quick, proper post-flood treatment, you can minimize the damage. We will walk you through the necessary steps to handle your robots after they have been exposed to standing water.

5 Ways to Prevent Robotic Automation Downtime

Smart manufacturers run highly productive operations by focusing on efficiency and increasing uptime. Doing this means implementing strategies to educate robot operators as much as possible on topics such as inspection, parts and service, preventive maintenance and more.

Avangrid Pilots Mobile Robot Dog to Advance Substation Inspections with Artificial Intelligence

Company collaborating with Levatas and Boston Dynamics to launch pilot project. Among utility industry's pioneers using artificial intelligence to detect and analyze substation equipment

Study: Robots and AI Offer Significant Carbon Emissions Reductions by Operating Centuries Old Industries Better

By incorporating better use of data into some of the world's most carbon-dependent industries, the study found the equivalent of up to 18% of U.S. emissions could be eliminated by better operation.

ABB survey reveals unplanned downtime costs $103,000 per hour

It emphasizes the importance of effective maintenance strategies and service partnerships. 92% of respondents are interested in how outcome-based maintenance agreements can boost business success

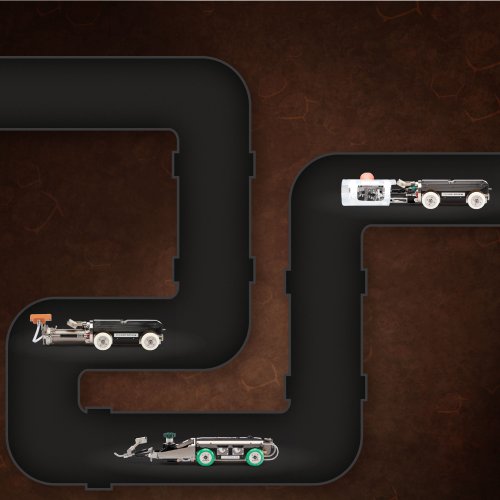

Minimally Invasive Sewage Renovation

As is the case with any type of infrastructure, sewers require regular maintenance. But the often narrow pipes below the ground are difficult to access.

Sarcos Successfully Executes Field Trials Demonstrating Suite of Robotic Technologies for Maintenance, Inspection, and Repair in Shipyard Operations

Sarcos robotic systems are designed to carry out maintenance, inspection, and repair activities, on and around ships that are underway and pier side, creating safer and more effective shipyard operations and improving the efficiency of sailors and shipyard workers.

Robots for Inspection and Maintenance Tasks

Inspection and maintenance tasks are a fundamental part of many industrial sectors: deteriorated infrastructures, tunnels, refineries, old buildings…

Boston Dynamics and IBM Join Forces to Bring Mobile Edge Analytics to Industrial Operations

The demand for AI-driven robotics is increasing in operations like those in manufacturing and warehouse settings to help organizations with data and analytics that identify problems in real time, improve decision making, and perform tasks more efficiently.

Retrofitting Older Machines Provides Valuable IIoT Update

Retrofit machines can bring legacy devices into the Internet of Things. Sensors and digital controls provide valuable information and integrate older machines into new, intelligent factory management systems.

Robotics and the Resumption of MRO Activities

Our recent discussions with key players in the field confirm that MRO's operations will increase significantly in late 2021 or 2022. How will maintenance centres efficiently restart their operations? What impact can technology have in this recovery?

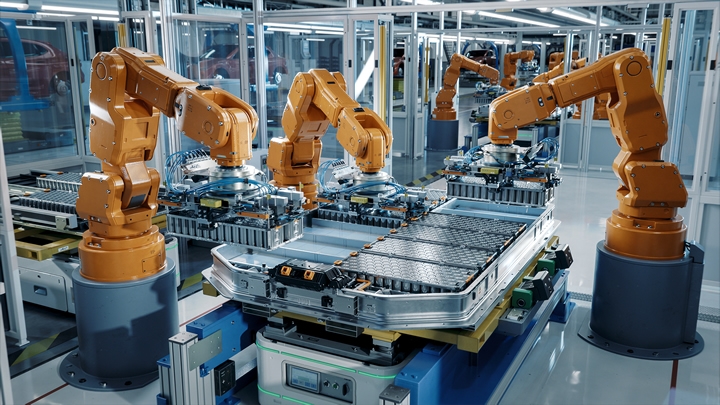

Making Robotic Systems Maintenance Easy at Kuka

Ease-of-use is a key element for improving maintenance pains for electronics manufacturers. When the robotic cell is designed for simplicity, it makes maintenance and management much easier for electronic manufacturers.

Records 1 to 15 of 18

Featured Product

REIKU's Cable Saver™ - The Most Versatile Modular Robotic Cable Management Solution

REIKU's Cable Saver™ Solution eliminates downtime, loss of revenue, expensive cable and hose replacement costs, maintenance labor costs. It's available in three sizes 36, 52 and 70 mm.

All of the robots cables and hoses are protected when routed through the Cable Saver™ corrugated tubing.The Cable Saver™ uses a spring retraction system housed inside the Energy Tube™ to keep this service loop out of harms way in safe location at the rear of the Robot when not required. The Cable Saver™ is a COMPLETE solution for any make or model of robot. It installs quickly-on either side of the robot and has been tested to resist over 15 million repetitive cycles.

REIKU is committed to providing the most modular, effective options for ensuring your robotic components operate without downtime due to cable management.

www.CableSaver.com