Facility Maintenance: Lavo Bot AI and NVIDIA Bring Autonomy to Exterior Surface Cleaning

Equipped with advanced mapping, multi-sensor vision and zone-based safety, the system navigates real-job sites with confidence—handling up to 6,000 sq ft/hour and supporting pressure-wash rigs up to 12 GPM and 4,500 PSI.

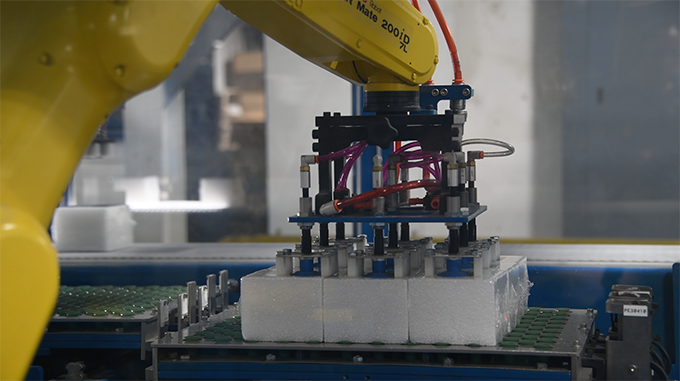

Robot-Driven Manufacturing Enables "Lights-Out" Production

The required solution would need to provide seamless connectivity and communication with the RoboDrill machines, as well as additional factory machinery throughout the company targeted for robotic automation moving forward.

UR20 Cobot Enables New Palletizing Opportunity at Bob's Red Mill

While the milling process is based on historic tradition, the company's packaging and product handling takes a high-tech approach: "Our vision is to double the number of people eating Bob's Red Mill by 2030. Automation will help us reach that goal."

Case Study Evaluation of an Auditory Alert for an Autonomous Mobile Robot

In this case study, we focus on the autonomous mobile robot (AMR), which can navigate and perform tasks in active environments without direct human control. Safe navigation and obstacle avoidance are fundamentally important for AMRs in the workplace.

Giving lens cleaning cloths a robotic hand - Robotic automation for textile processing

Here's how Italian startup, Roboprint, partnered with TM Robotics, the distributor of Shibaura Machine robots, to develop an automated solution for the labour-intensive processes of detaching and handling eyeglasses fabric stock.

Jasper Group Using AMRs for Material Handling

Jasper Group turned to a systems integrator, Robotic Solutions, LLC, to help them consider using autonomous mobile robots (AMRs) for material handling in a plant of more than one-million square feet"¯of manufacturing space.

Machine Vision meets every taste

Ensuring safety and accuracy of correct packaging is a high priority in the food industry. In addition to the packaging quality, the high variation of different packaging and labeling is also a challenge.

Global cricket ball manufacturer uses automation with a vision system for efficiency and upskilling

The plan was to place the full trays of cricket ball covers into the dispenser, feeding trays automatically to the TVL700 robot to load and unload the trimming machine. This requires only one operator to load a set of trays every 20 to 25 minutes.

Chemical Manufacturing Leader Polysciences Partners With Formic to Introduce Automation To Their Production Process

With a unique capability of offering concept-to-commercialization services to their clients, making continuous production improvements for commercialization is a key focus.

Customer Renews Contract as Cyngn's Autonomous Vehicles Yield 4x Efficiency Gain

USC has enjoyed tremendous growth over the three decades it's been in business. The company has become familiar with the hurdles intrinsic to manufacturing and distribution: supply chain disruptions, soaring labor costs, and the relentless pursuit of operational efficiency.

Delica Drives Efficiency with AGV Installation

Delica selected a Stöcklin AGV with BlueBotics' ANT navigation technology to automate their materials handling between production and logistics.

The World's First Dual-Arm Autonomous Robotic Sanding Cell

GrayMatter Robotics and BetterWay Products Inc. Revolutionize Marine Manufacturing with Cutting-Edge Robotic Innovation

Insights from Brenton Engineering Company

Equipment Flexibility Key to Accommodating Changing Applications , The Upside of Automation on Your End-of-Line Operation, The Value of Project Management

FORVIA

Currently in the PÃsek location, 14 MiR robots are deployed. 7 of them, heavy duty MiR robots, mainly MiR600s, work in the area of finished goods, bringing empty pallets to the assembly lines and picking up full pallets to the logistics area.

Universal Robots - Centercode Case Study

Universal Robots sought a partner to help transform their traditional, ad hoc, check-the-box user testing program into an efficient source of actionable product feedback to give them a significant edge on their competition.

Records 1 to 15 of 55

Featured Product

3D Vision: Ensenso B now also available as a mono version!

This compact 3D camera series combines a very short working distance, a large field of view and a high depth of field - perfect for bin picking applications. With its ability to capture multiple objects over a large area, it can help robots empty containers more efficiently. Now available from IDS Imaging Development Systems. In the color version of the Ensenso B, the stereo system is equipped with two RGB image sensors. This saves additional sensors and reduces installation space and hardware costs. Now, you can also choose your model to be equipped with two 5 MP mono sensors, achieving impressively high spatial precision. With enhanced sharpness and accuracy, you can tackle applications where absolute precision is essential. The great strength of the Ensenso B lies in the very precise detection of objects at close range. It offers a wide field of view and an impressively high depth of field. This means that the area in which an object is in focus is unusually large. At a distance of 30 centimetres between the camera and the object, the Z-accuracy is approx. 0.1 millimetres. The maximum working distance is 2 meters. This 3D camera series complies with protection class IP65/67 and is ideal for use in industrial environments.

Robotics and Automation - Featured Company

ResinDek / Cornerstone Specialty Wood Products

As the manufacturer of ResinDek® panels, we have been at the forefront of testing and innovating flooring panels for the Material Handling Industry since 1994. In 2007, we began providing ResinDek panels for automated warehouse distribution robots. Much of our initial research and development occurred with Automated Guided Vehicles. In the last decade, we have provided a variety of ResinDek engineered flooring products to numerous Automated Guided Vehicles (AGV) and Autonomous Mobile Robot (AMR) manufacturers for their testing labs. As a result, millions of square feet of ResinDek panels are in service worldwide with robotic traffic in distribution centers, warehouses, microfulfillment centers, and retail environments.