How to Successfully Automate Packaging in Low-volume, High-mix Production

Recent advances in robotic programming have reduced the implementation time of robotic automation to a point where even small and medium sized manufacturers with high-mix, low-volume production can get a robotic packaging application up and running in just a few hours

Why Are You Still Manually Programming Your Robot?

Robots were first introduced to manufacturing assembly lines in 1978. Since then, the hardware (mechanics and control systems) has improved significantly. Yet the way these robots are programmed has not changed very much.

Making Robotic Programming Easier for the Fabrication Industry

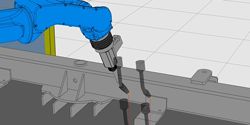

OLRP provides a virtual environment to complete robot programming without taking the robot offline, thereby simplifying complex and time-consuming programming.

Calculating the ROI of Offline Robot Programming Software

Capital investments in advanced manufacturing environments require careful consideration, especially if that investment is for a new process or technology. If you are looking at"¯investing in OLP here are some things to consider about the potential return on investment (ROI).

Records 1 to 4 of 4

Featured Product

ResinDek TRIGARD ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC (www.resindek.com) created the TriGard ESD Ultra finish for its ResinDek engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Robotics and Automation - Featured Company

TM Robotics (Americas) Inc

TM Robotics, in partnership with Shibaura Machine, formerly known as Toshiba Machine until 1st April 2020, offers a comprehensive range of industrial robots ideally suited for high-precision assembly, machine loading/unloading and material-handling applications that can be dust proof, clean room, or IP65/67. The company's extensive product line starts with a Cartesian solution available in thousands of combinations from single actuators to four-axis solutions; six-axis solutions that can include precise vision-control; and a complete range of SCARAs from low cost to the industry-leading SCARA with 1200-mm reach that can carry up to 20 kgs. TM Robotics sells and services robots throughout Europe, the Middle East, India, Russia, and Africa, as well as North, Central, and South America, from headquarters in Hertfordshire, England and Elk Grove Village, IL, USA. For more information, visit www.tmrobotics.com or follow us on Twitter, LinkedIn and YouTube.