UAV Systems Development - Challenges for ISTAR Support

DSEi 2011 - Events to be staged in the Robotics and Unmanned Systems Showcase

‘UAV Systems Development - Challenges for ISTAR Support is the title of a briefing to be given by Cranfield Universitys Professor Ian Poll. Cranfield Aerospace, a wholly owned subsidiary of the university, has a growing capability in the field of Unmanned Air Systems (UAS), with a proven track record in the development of innovative systems. From 11:45 to 12:30, Tues 13 Sept.

Under the heading ‘UAV Hangars in Harsh Climes Sprung Instant Structuress International Sales Manager, Jonathon Fenton, will report on a climate controlled hangar for one of the largest UAVs in operation which has been installed in one of the hottest places on the planet. From 14:00 to 14:30, Tues 13 Sept.

Accumulating flight hours faster than any other mid-endurance UAV System, Insitus ScanEagle UAS is also the most employable, with a mission-readiness record exceeding 99 per cent. In Sustaining Scan Eagle's 500,000 Flight Hours - the Future of Unmanned Missions, Insitus International Business Development Director Steve Tanner reviews this impressive capability between 14:45 and 15:15, Tues 13 Sept.

A demonstration entitled ‘Foot Patrol in Afghanistan featuring unmanned air and ground systems, will be staged twice daily at 10:30 and 15:30.

The Robotics and Unmanned Systems Showcase is located in the north west corner of the North Halls - nearest entrance N3.

For information on other seminars happening during DSEi visit http://goo.gl/Hmy3z.

These seminars are open to registered attendees of DSEi 2011. To register visit www.dsei.co.uk/register

Featured Product

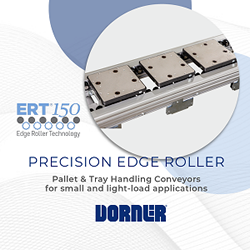

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.