Matrox Imaging to Demonstrate New Machine Vision Hardware and Software at Automate 2013

Montreal, Canada - At Automate 2013 (January 21-24, Chicago, IL), Matrox Imaging will demonstrate new hardware and software for industrial imaging and machine vision, including Matrox Design Assistant 3.0, the latest release of its flowchart-based integrated development environment (IDE) for the Matrox Iris GT smart camera line.

Visit the Matrox Imaging booth (McCormick Place North, #933) and see:

*Multiple Matrox Iris GT smart cameras being monitored and controlled remotely from a single HMI application, which is included with Matrox Design Assistant smart camera software. Design Assistant 3.0 makes it even faster and easier for users to create their application's flowchart and HMI.

*High-speed surface inspection using a 16k-pixel, 100 kHz line rate, 4 links, CoaXPress line-scan camera interfaced to a Matrox Radient eV-CXP frame grabber board in a Matrox Supersight imaging computer. The Supersight supports multiple multi-core CPU / GPU-based compute nodes running the Matrox Imaging Library (MIL).

About Matrox Imaging

Established in 1976, Matrox Imaging is a leading developer of component-level solutions for machine vision, image analysis, medical imaging, and video surveillance. Products include frame grabbers, vision processors, imaging computers, industrial and smart cameras, and application development software. Headquartered in Montreal, Quebec, Canada, Matrox is a privately held company with offices in the United Kingdom, Ireland, Germany, and Hong Kong. For more company information, visit "About Matrox Imaging".

Featured Product

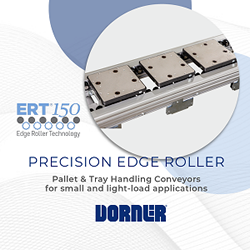

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.