Adept Technology Wins 2.5 Million Dollars in Orders from Two Digital Storage Companies

Adept has served the digital storage and broader electronics industries with leading-edge robotics and controls in both standard and cleanroom configurations for more than 25 years.

Pleasanton, Calif., June 22, 2015 - Adept Technology, Inc. (Nasdaq:ADEP), a

services, has received orders over the last several weeks totaling more than

2.5 million dollars (US Dollar) for its industrial robot products from two

global companies in the digital storage industry. Shipments began in May and

are scheduled to continue through October 2015.

"Adept's industry-leading Cobra and Python robots are ideal for the highly

reliable, precision production that is the foundation of the electronics

industry, and in particular, digital storage manufacturing," said Rob Cain,

president and CEO at Adept. "These prominent global companies selected Adept

for our robots' proven performance, and the field support we provide to our

customers worldwide."

Adept has served the digital storage and broader electronics industries with

leading-edge robotics and controls in both standard and cleanroom

configurations for more than 25 years. Adept industrial robots meet strict

cleanroom requirements, and provide repeatable precision assembly,

performing to tight tolerances. Other key benefits include integrated

machine vision and compact controls that govern multiple robots.

About Adept Technology, Inc.

Adept is a global, leading provider of intelligent robots, autonomous mobile

robot solutions, and services that enable customers to achieve precision,

speed, quality and productivity in their assembly, handling, packaging,

testing, and logistical processes. With a comprehensive portfolio of

high-performance motion controllers, application development software,

vision-guidance technology and high-reliability robot mechanisms with

autonomous capabilities, Adept provides specialized, cost-effective robotics

systems and services to high-growth markets including medical, electronics,

food and semiconductor; as well as to traditional industrial markets

including machine tool automation and automotive components. More

information is available at www.adept.com.

Featured Product

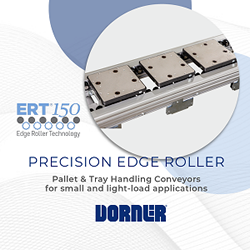

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.