Harmonic Drive LLC to demo Mars 2020 Rover Arm at Robobusiness

Motive Space Systems brings arm to exhibit with Harmonic Drive

Peabody, MA -Harmonic Drive LLC, a leader in high precision motion control is featuring Motivs Mars 2020 Rover Arm at Robobusiness 2017 in Santa Clara September 27 & 28. The arm will be on display in Harmonic Drives booth #304.

The fully-functioning 7-foot arm will be demonstrating its capabilities throughout the show. Five degrees of freedom enables the arm to move much link a human arm. The team from both Harmonic Drive and Motiv Space Systems will be on-site and available to answer any questions.

Here is some more about the arm from the Nasa website: Mars 2020's 7-foot-long robotic arm can move a lot like yours. It has a shoulder, elbow and wrist "joints" for maximum flexibility. The arm lets the rover work as a human geologist would: by holding and using science tools with its "hand" or turret. The rover's own "hand tools" extract cores from rocks, takes microscopic images and analyzes the elemental composition and mineral makeup of Martian rocks and soil.

About Harmonic Drive LLC

Harmonic Drive, LLC engineers and manufactures precision servo actuators, gearheads and gear component sets. We work closely with both Fortune 500 and companies of all sizes to understand their application requirements and provide a standard or custom-engineered solution to enable the success of their design project. The majority of the products sold by Harmonic Drive, LLC are proudly made at our manufacturing facility in Peabody, Massachusetts. Harmonic Drive Group Companies in, Japan (Harmonic Drive Systems, Inc.) and Germany (Harmonic Drive AG) provide additional products. We have shared core values, product designs and quality standards. State of the art manufacturing facilities in the US, Japan and Germany enables us to locally serve the needs of our global customers.

With over 50 years of experience, our expert engineering and production teams develop enabling technologies and products to meet the needs of an evolving motion control market. We are very proud of our outstanding company history. Our high-precision, zero-backlash Harmonic Drive® gears and Harmonic Planetary® gears have, and continue to play critical roles in robotics, spaceflight applications, semiconductor manufacturing equipment, factory automation equipment, medical diagnostics and surgical robotics.

Harmonic Drive is a registered trademark of Harmonic Drive Systems.

Featured Product

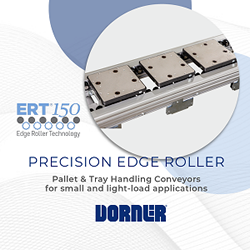

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.