AV Unveils New AI Capability and Autonomy Kit for Unmanned Systems

AV’s Autonomy Retrofit Kit (ARK) and AVACORE software deliver a suite of new single or multi-agent mission capabilities to autonomous systems

AeroVironment (AV) has introduced its Autonomy Retrofit Kit (ARK) and AVACORE software demonstrating the company's commitment to advancing autonomy and machine learning capabilities to increase effectiveness of autonomous systems and reduce operator burdens. ARK and AVACORE bring AV's accelerated autonomy to fielded assets such as Puma™ 3 AE and Puma™ LE, in addition to future autonomous systems.

ARK is a quick-connect payload introducing a new suite of intelligent mission capabilities for Group 1+ unmanned aircraft systems (UAS). Providing edge computing for mission-critical applications, ARK enables operators to task a single or multi-vehicle team with mission objectives for fully autonomous execution while operating in communications-contested environments. ARK also intelligently integrates with distributed groups of dismounted units in a Mobile Ad Hoc Network (MANET) using the Android Team Awareness Kit (ATAK).

AVACORE is AV's autonomy software providing an open framework for unmanned systems. It features a modular set of interfaces such as autopilots, radios and sensors, and supports rapid integration with new platforms and applications. ARK also comes preinstalled with SPOTR-Edge, AV's computer vision software, for onboard detection, classification, localization, and tracking of operationally relevant objects including people, vehicles, aircraft, and maritime vessels, day or night.

"ARK and AVACORE provide enhanced capabilities and critical advantages to warfighters on complex battlefields," said AV's Senior Vice President of MacCready Works, Jeff Rodrian. "This payload combines AV's unparalleled autonomy and field-proven computer vision SPOTR-Edge to accelerate awareness and mission success."

Though the combination of autonomy and computer vision, ARK and AVACORE allow operators to select a wide variety of single or multi-agent capabilities including multi-region search, track and follow and more. The introduction of these systems builds upon AV's proven and trusted family of autonomous systems, bringing a scalable, adaptable AI toolset to fielded and new assets for safer, smarter mission capabilities.

"AVACORE features an intuitive behavior tree approach allowing flexibility for rapid development and adoption of new autonomous missions," continued Rodrian. "This results in smarter systems with reduced cognitive load for warfighters."

Click here to request additional information on AV's ARK and AVACORE.

ABOUT AEROVIRONMENT

AeroVironment (NASDAQ: AVAV) is a global leader in intelligent multi-domain robotic systems, uncrewed aircraft and ground systems, sensors, software analytics and connectivity. Headquartered in Arlington, Virginia, AeroVironment delivers actionable intelligence so our customers can proceed with certainty. For more information, visit www.avinc.com.

Featured Product

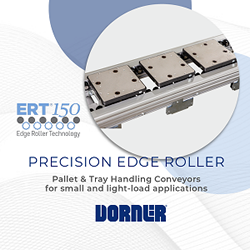

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.