Elevating Precision Motion and Control with Magnetic Levitation to New Heights

What sets magnetic levitation apart is the ability to create a contactless, ultra-high-precision virtual bearing within our control system". Dr. Christian Rudolf provides a glimpse into the exciting development journey of PI's magnetic levitation solutions.

Case Study: Delta Line Motion System Solutions for Robotics

Delta Line motors, particularly those in its rapidly expanding frameless range, offer exceptional power density and are well suited to meet the need for compact yet powerful motion solutions.

Drives for Speed in Intralogistics

Competitive intralogistics requires extensive automation, something that is inconceivable without micromotors. Drive systems from FAULHABER prove their ability to perform here during sorting, transporting and with robotics solutions.

The Importance of the Speed-Torque Gradient in DC Motor Sizing

The speed / torque gradient is an indicator of a motor's performance. The smaller the value, the more powerful the motor and consequently the less motor speed varies with load variations. It is based on the quotient of ideal no-load speed and ideal stall torque.

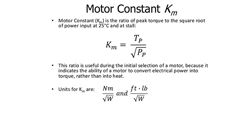

Understanding the Motor Constant in DC Motor Sizing

One of the most often overlooked parameters of direct current motors (both brush and brushless) is the Km or motor constant. The motor constant (expressed as Km) defines the ability of a motor to transform electrical power into mechanical power.

RoboticsTomorrow.com - Q&A with ElecroCraft

We provide motion control solutions in the form of electric motors, drives and motion control solutions for OEM Customers who are unsatisfied with having to design around inflexible off-the-shelf products.

Slotless Brushless Servo Motors Improve Machine Performance.

From the outside it looks just like any other industrial brushless servo motor but inside it utilized advanced manufacturing techniques to provide higher torque, higher speed, smoother operation, higher efficiency, and better inertial matching in a smaller package.

Power Density in Robotics

One of the basic requirements for the drives of mobile robots is high power density. For robots, this usually means high torque while taking up the smallest possible space.

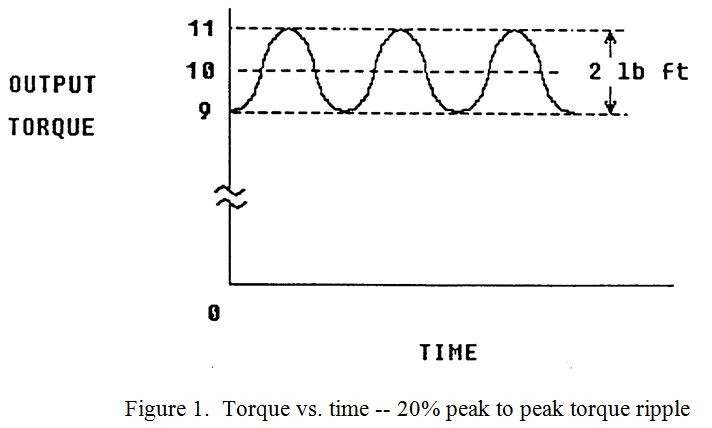

Understanding Torque Ripple in Servo Motors

Torque ripple must be defined as a function of output load and speed. For load specification the most sensible rating point is the continuous duty thermal torque rating for the servo motor.

These Robots Crawl Into Every Nook and Cranny

The latest addition is a small crawler robot that magnetically "sticks" to metal walls and is able to move in all directions. It carries cameras, sensors and tools for inspection or maintenance work in tight pipes and on the outer hulls of tanks or ships.

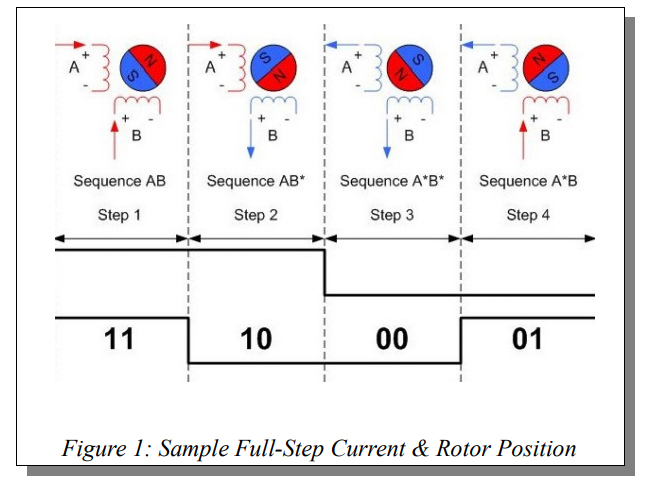

Forms of Closed Loop Stepper Control

2017 - Most Popular Article - To achieve the highest performance, the stepper motor can be treated as a 2 phase brushless servo motor. Current to the motor will then be controlled as a function of the error signal just as with standard servo motors.

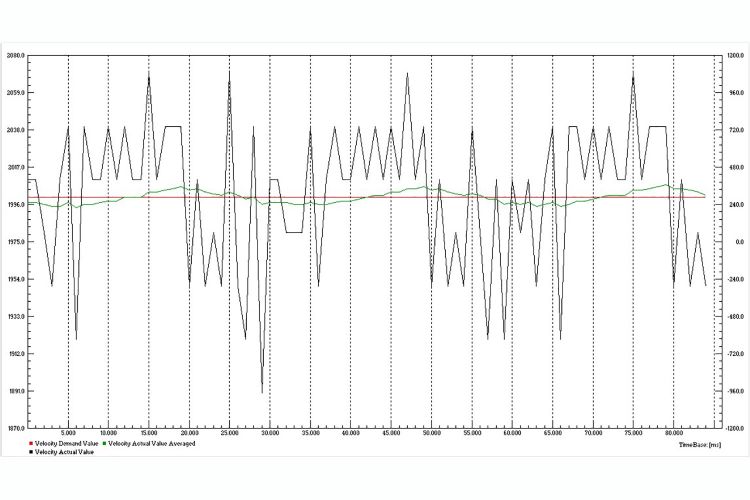

Encoder Selection: Speed Control

A general in depth analysis shows that the highest encoder resolutions are required for very precise speed control. The encoder resolution increases with the square of the demanded speed accuracy.

Development of Battery-Free Multi-Rotation Absolute Encoder

In recent years, there have been many demands for equipment with high productivity to have a system that retains positioning information, even after the main power supply is turned off.

Records 1 to 13 of 13

Featured Product

The ERT150 - Dorner's Next Evolution of Edge Roller Technology Conveyors

The next evolution in Dorner's Edge Roller Technology conveyor platform, the ERT®150, is ideal for small and light-load assembly automation, as well as medical and medical-device assembly application. The ERT platform is the only pallet conveyor of its kind available with an ISO Standard Class 4 rating for cleanroom applications. Earning the ISO Standard 14644-1 Class 4 rating means Dorner's ERT150 will conform and not contribute to the contamination of cleanrooms to those standards. As implied by its name, the ERT150 (Edge Roller Technology) uses rollers to move pallets through the conveyor smoothly with no friction (a byproduct often seen in belt-driven platforms). The conveyor's open design eliminates concerns of small parts or screws dropping into rollers and causing conveyor damage or jamming. The ERT150 is suited to operate in cleanroom environments requiring a pallet handling conveyor. It is capable of zoning for no or low-back pressure accumulation and is ideal for automation assembly applications within industries including medical devices, electronics, consumer goods among others.

.jpg)

.jpg)