How to Successfully Automate Packaging in Low-volume, High-mix Production

Recent advances in robotic programming have reduced the implementation time of robotic automation to a point where even small and medium sized manufacturers with high-mix, low-volume production can get a robotic packaging application up and running in just a few hours

Why Are You Still Manually Programming Your Robot?

Robots were first introduced to manufacturing assembly lines in 1978. Since then, the hardware (mechanics and control systems) has improved significantly. Yet the way these robots are programmed has not changed very much.

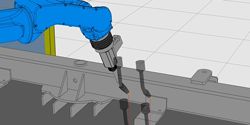

Making Robotic Programming Easier for the Fabrication Industry

OLRP provides a virtual environment to complete robot programming without taking the robot offline, thereby simplifying complex and time-consuming programming.

Calculating the ROI of Offline Robot Programming Software

Capital investments in advanced manufacturing environments require careful consideration, especially if that investment is for a new process or technology. If you are looking at"¯investing in OLP here are some things to consider about the potential return on investment (ROI).

Records 1 to 4 of 4

Featured Product

CMES - AI-Powered 3D Robot Vision

Powered by AI, CMES Robotics enables 3D vision for factory robots. CMES AI vision software enables robots to recognize unstructured, flexible, or deformed objects, pick them up, and loading and unloading. CMES Vision software has been deployed worldwide for random palletization and depalletization along with void filling applications. CMES Robotics automates your warehouse, logistics, and supply chain. For more information, please visit: cmesrobotics.com or email info@cmesrobotics.com.

Robotics and Automation - Featured Company

PNY

PNY Professional Solutions provides customers with powerful tools to manage heavy workloads. PNY offers NVIDIA Professional, Consumer GeForce RTX, and Data Center GPU Solutions, along with PNY Memory upgrades and Solid-State Drives. All PNY products are designed and built with system integrators in mind to provide advanced application performance, top productivity, and greater power efficiency.