If your application requires drive systems, stop by the maxon booth to see the latest in dc brushed, brushless and geared motor technology. We offer standard, semi-custom and fully customized drive solutions and our experts are there to help guide you.

Automate 2025 Q&A with maxon group

Automate 2025 Q&A with maxon group

Q&A with | maxon group

Tell us about your company.

maxon is a global leader in the design, manufacturing, and engineering services of high-precision drive solutions. We work closely with our customers to develop innovative product solutions that precisely meet the unique operating requirements of individual systems.

Your company will be exhibiting at Automate, what is it that makes this an important event for your company?

AUTOMATE is a perfect event to showcase maxon and Parvalux’s drive technology. Our drive systems are used in a wide variety of material handling applications, including: AGVs, conveyors, sorting machines, pallet and tray shuttles, warehouse tugs, ASRS storage and retrieval systems, packaging, and labeling systems, and much more.

AUTOMATE is a perfect event to showcase maxon and Parvalux’s drive technology. Our drive systems are used in a wide variety of material handling applications, including: AGVs, conveyors, sorting machines, pallet and tray shuttles, warehouse tugs, ASRS storage and retrieval systems, packaging, and labeling systems, and much more.

What makes your booth a must visit for Automate Attendees?

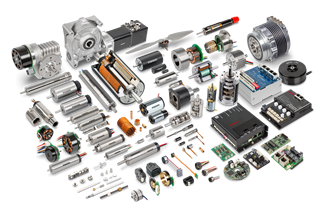

If your application requires drive systems, stop by the maxon booth to see the latest in dc brushed, brushless and geared motor technology. We offer standard, semi-custom and fully customized drive solutions and our experts are there to help guide you to the best solution for your application needs. We will be showcasing the Parvalux Modular Range of motors and gearboxes at this year’s event. The modular range features brushed and brushless motors, an extensive list of gearboxes and a selection of accessories to fine tune your custom configuration. This range of motors and gearboxes is available as a rapid prototype for quick integration within your application. They are quick to configure, quick to build and quick to deliver. Visit our website to learn more!

If your application requires drive systems, stop by the maxon booth to see the latest in dc brushed, brushless and geared motor technology. We offer standard, semi-custom and fully customized drive solutions and our experts are there to help guide you to the best solution for your application needs. We will be showcasing the Parvalux Modular Range of motors and gearboxes at this year’s event. The modular range features brushed and brushless motors, an extensive list of gearboxes and a selection of accessories to fine tune your custom configuration. This range of motors and gearboxes is available as a rapid prototype for quick integration within your application. They are quick to configure, quick to build and quick to deliver. Visit our website to learn more!

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see? Any educational sessions, pavilions etc. you plan on attending?

We are most interested in learning about industry trends, new market needs and where the future of the industry is headed. This helps us to understand the market needs more and how we can help to drive technology forward in the years to come.

Manufacturing is undertaking rapid advancements, be it automation, robotics and of course AI. How is your companies services and products utilizing AI now to improve business?

The rate that manufacturing and AI are advancing is incredible. maxon is embracing the use of AI to help us push the limits of drive technology to meet the future needs of the industry. Our motors and controllers are robust, cost effective, compact, and reliable solutions that will help take your application to the next level. Our latest developments in motion control feature multiple interfaces and inputs and can be integrated easily into your application.

Give us your thoughts on what the future holds for manufacturers and automation.

At maxon, we believe that the future of automation and manufacturing will be centered on the use of robotics and automation. Robotics is changing rapidly, and we’re excited to be able to work with leading manufacturers on ensuring that they are selecting the right drive systems for their applications.

At maxon, we believe that the future of automation and manufacturing will be centered on the use of robotics and automation. Robotics is changing rapidly, and we’re excited to be able to work with leading manufacturers on ensuring that they are selecting the right drive systems for their applications.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

Understanding Torque and Speed in Electric Motors

How Parvalux Is Helping to Develop the Next Generation of Conveyor Systems

Robots speeding up material handling

More about maxon group

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product