Anyware Robotics Emerges from Stealth Mode to Reveal Its Pixmo Robots for Container and Truck Unloading

Anyware Robotics today emerged from stealth mode to unveil its AI-powered robotic solution, Pixmo, for container and truck unloading. Every year an estimated 28 million containers enter the US with contents, usually boxes, that need to be unloaded. Anyware Robotics Pixmo robots enable companies to ease the heavy burden on human workers who currently unload these. The versatile mobile robots autonomously unload boxes in containers and trucks more safely, cost-effectively, reliably, and quickly than humans can – without the related injuries.

The autonomous mobile Pixmo robots are ideal for unloading at transload facilities, cross docks, third-party logistics providers (3PLs), distribution centers, and e-commerce fulfillment warehouses. The robots can be installed within days and provide enhanced operational efficiencies and predictability.

Anyware Robotics was founded in January 2023, raised $5 million in seed capital in March 2023, and is actively negotiating another round of funding to accelerate bringing Pixmo to market. The robotic solution was developed based on years of intensive robotics research by the founders, as well as the personal experience of the company’s CTO unloading containers for his parents’ warehousing business.

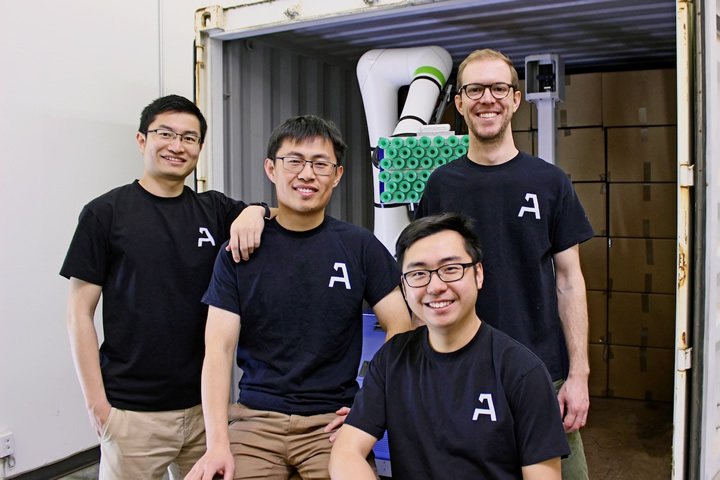

Three of Anyware Robotics founders earned robotics PhDs at University of California, Berkeley, and collectively have 25 robotics patents. Two worked at major robotics supplier FANUC, one as a founding member of the FANUC Advanced Research Lab, and one on the commercialization of AI-powered robotic solutions there. A fourth founder held various senior roles at another logistics robot provider.

“Truck unloading is an excellent example of where robots can greatly contribute to making the world a better place,” said Thomas Tang, CEO and co-founder of Anyware Robotics. “Humans have been doing an admirable job in that heavy and demanding work, but there are too many injuries. Pixmo can help to significantly reduce those injuries while improving the throughput of the logistics operations.”

Pilot Programs are Leading to Pixmo Sales

Anyware Robotics is currently running pilot programs of Pixmo with various companies in the US. They recently completed their first pilot with an import deconsolidation business that manages 21 warehouses in the US. The company met the client’s throughput requirement and converted it into a sale of multiple Pixmo robots. Looking forward, Anyware Robotics has multiple upcoming pilots, including one with a leading global third-party logistics provider.

Loading docks are usually the most hazardous area for humans in the warehouse. Companies, in turn, are faced with costly labor, high turnover, reliability issues, and labor capacity that is not always aligned with the ever-changing throughput needs of the facility. The Anyware Robotics solution can reduce labor costs on the receiving dock up to 60%.

Pixmo Uses AI and Machine Learning to Maximize Productivity, Precision, and Safety

The Anyware Robotics solution combines an autonomous mobile robot (AMR) base, a cobot arm with six degrees of freedom, vacuum-powered end effector designed for case handling, and AI-powered perception and motion planning systems. It does not require costly software integrations or infrastructure changes to be deployed into the warehouse environment. With its mobile base that has the footprint of a warehouse pallet, the Pixmo robot can move in any direction to create the best handling pose for the robot arm, both in and outside the container.

Pixmo is built on an advanced AI software stack that combines the latest perception algorithms, learning-based motion planning, and a state-of-the-art data generation pipeline for AI training. The adaptive approach enables Pixmo to be deployed quickly on-site, adjusting and learning on the fly and continuously enhancing reliability. It also enables it to easily manage the complexity of shifting boxes during transit, box orientation, box size, number of SKUs, carton sizing, and packaging quality.

Safety is a key element of the Anyware Robotics solution. Pixmo is the first and only robot in the category that uses a force sensing cobot arm for unloading. This important capability gives warehouse managers peace of mind that the robot can safely work in environments where humans may suddenly move into its path.

“Automated truck and container unloading is a nascent market,” continued Thomas Tang, CEO of Anyware Robotics. “Our robotic solution strikes a balance between capability and cost effectiveness, plus it adds a strong safety component. The safety features help enable the great versatility of Pixmo in the future.”

While Anyware Robotics is focused on the massive need in truck unloading now, the flexible form factor of the Pixmo robot means that in the future (with additional applications software through over-the-air updates) the robot can also be used for a variety of other tasks within the warehouse. These capabilities may include palletizing, depalletizing, case picking, container loading, and other tasks, which will further enhance the ROI of the robots.

Availability of Pixmo

The commercial version of Pixmo is scheduled to be available in the summer of 2024. It will be available via direct purchase or RaaS (robots-as-a-service) models enabling companies that use Pixmo to easily scale as their business grows. Companies interested in participating in a Pixmo pilot program may contact Anyware Robotics via their website.

Pixmo robots will be demonstrated publicly for the first time at Booth A11227 at MODEX, March 11-14, 2024, in Atlanta, GA.

About Anyware Robotics

Anyware Robotics unloads hassle from your logistics operations. We believe robots are the way to ease the heavy burden on workers who unload boxes from trucks. Our company offers versatile AI-powered mobile robots that autonomously unload boxes in containers and trucks more safely, cost-effectively, reliably, and quickly. They can be installed within days and provide enhanced operational efficiencies and predictability. Founded in January 2023 by four AI and robotics industry veterans, the company is based in Fremont, CA. More information at: www.anyware-robotics.com

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product