Semiconductor Innovations for the Next Generation of Robots

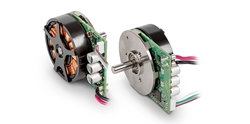

Each motor requires high power density and precise control, all packed into a small form factor. TI's technology reduces the size of the board by integrating FETs, drivers and current sensing into one package.

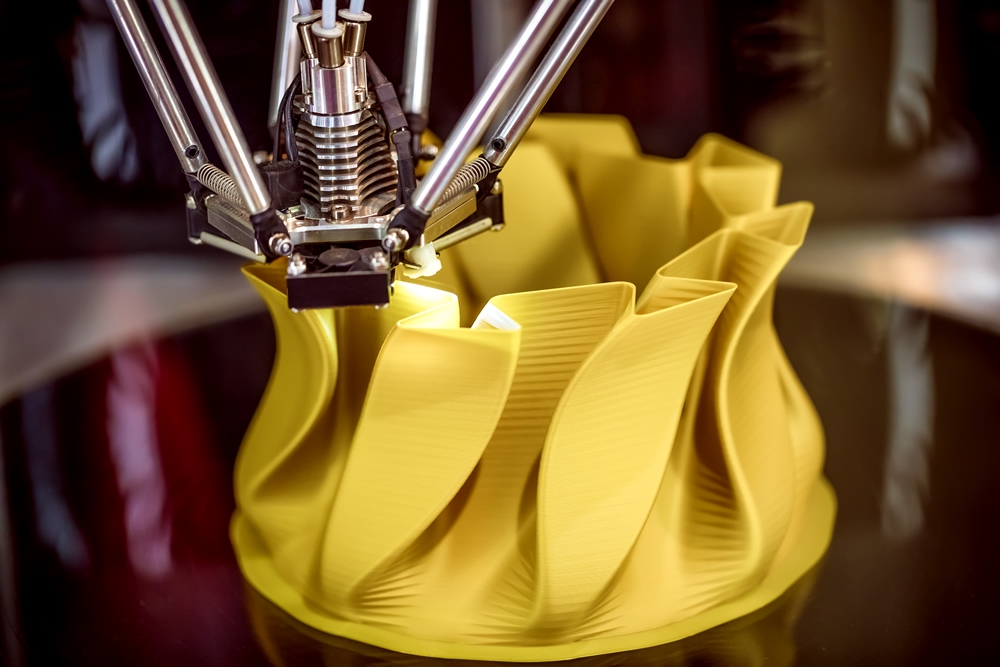

What are the motion control requirements for additive manufacturing machines?

3D printed objects can include intricate machine components, through to edible items, and as a result, the additive material could range from powdered metals to chocolate. Whatever the material and shape required, functionally, the 3D printing technique is the same.

Optimizing Wheel Drives for AGVs and AMRs: What OEMs Need to Know About Motion Control

The motor and actuator selection behind each wheel can make or break the success of the entire system. In this post, we'll explore the core challenges in mobile robot drive systems and how customized motion control solutions from DINGS' Motion USA can help you meet them.

Elmo Launches New Titanium Product Line and Platinum Servo Drives at SPS 2025, Redefining Limits of Motion Control

Designed to deliver exceptional performance, industry-leading compactness, and advanced high-end technology, built for demanding industrial and harsh-environment applications.

High-Precision RV Reducers Perfectly Matched for Walking Robots

RV reducers provide extremely high rigidity, precision, and torque while maintaining a compact size and exceptional reliability, making them an ideal match for the demanding requirements of walking robot joints in terms of load capacity, impact resistance, and precision.

The Emergence of Mechatronic Subsystems and Their Importance in Product Deployment

A mechatronic subsystem is a fully integrated functional unit that combines mechanical, electrical, electromechanical, and control elements into a single pre-engineered solution.

Why Sensor Resolution Matters More Than You Think in Vibration Control

In high-precision motion control systems like those used in precision manufacturing, the terms "sensor resolution" and "servo bandwidth" are often tossed around interchangeably, sometimes even confused as being functionally synonymous. But they're not.

The Future of Underwater Robotics

Imagine a robot that can manage aquaculture projects, repair oil pipelines, and scan the seabed - all without risking human life. Nauticus Robotics' flagship robot, Aquanaut, meets these challenges while running solely on electric power.

Multi-axis motion control drives pipe-based robots

Surveying and maintaining underground pipes can be complex and resource intensive. To streamline the process, construction and facility management teams are increasingly turning to robots that can provide inspection as well as repair.

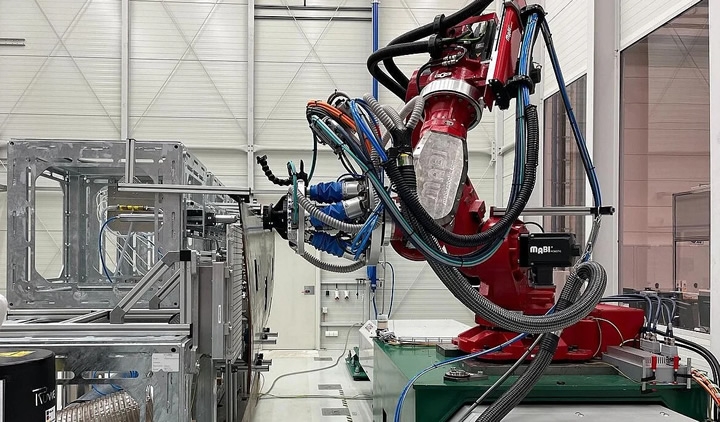

Press Brake Robots: Transforming Sheet Metal Bending with Precision and Efficiency

Press brake robots eliminate the challenges of manual sheet metal bending, such as inconsistencies, high labor costs, and workplace hazards. By leveraging robotic arms, sensors, and advanced software, these systems significantly improve accuracy and repeatability.

Developing robotic solutions: partnering for success in micro-motion control

To turn a motion concept into reality, dedicated engineering expertise can be invaluable. Not only can motion engineering support help to improve performance and reliability, but a design partnership can also optimize commercial viability - and reduce time to market.

Integrating Servo Drives with Robotics: Key Considerations for Seamless Automation

In this article, we will explore the key considerations for integrating servo drives with robotics to achieve smoother, more effective automation systems.

Fast Hexapod Improves Aircraft Manufacturing Process

PI presented a new, high-speed hexapod at the International Aerospace Exhibition ILA Berlin in June 2024, as a partner in the LuFo VI-1: ADMAS (Advanced Machining and Sealing) research project.

What Are the Secrets to Optimizing Motion Control in Robots?

Motion control optimization is about more than ensuring a robot can move. It must also move correctly; meeting the ideal speed, power, direction, length and timing. Assurance in each of these categories is necessary because these are what separate robots from human employees

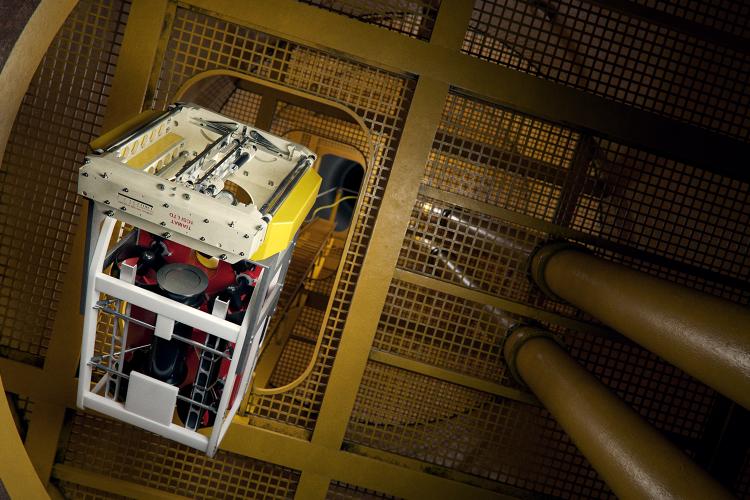

200 Times Faster Subsea Inspection

Precise motion control is helping a new subsea inspection device achieve highly accurate inspection with the fastest-yet speeds of data collection.

Records 1 to 15 of 63

Featured Product

Elmo Motion Control - The Platinum Line, a new era in servo control

Significantly enhanced servo performance, higher EtherCAT networking precision, richer servo operation capabilities, more feedback options, and certified smart Functional Safety. Elmo's industry-leading Platinum line of servo drives provides faster and more enhanced servo performance with wider bandwidth, higher resolutions, and advanced control for better results. Platinum drives offer precise EtherCAT networking, faster cycling, high synchronization, negligible jitters, and near-zero latency. They are fully synchronized to the servo loops and feature-rich feedback support, up to three feedbacks simultaneously (with two absolute encoders working simultaneously). The Platinum Line includes one of the world's smallest Functional Safety, and FSoE-certified servo drives with unique SIL capabilities.

Robotics and Automation - Featured Company

IDS Imaging Development Systems Inc.

World-class image processing and industrial cameras "Made in Germany". Machine vision systems from IDS are powerful and easy to use. IDS is a leading provider of area scan cameras with USB and GigE interfaces, 3D industrial cameras and industrial cameras with artificial intelligence. Industrial monitoring cameras with streaming and event recording complete the portfolio. One of IDS's key strengths is customized solutions. An experienced project team of hardware and software developers makes almost anything technically possible to meet individual specifications - from custom design and PCB electronics to specific connector configurations. Whether in an industrial or non-industrial setting: IDS cameras and sensors assist companies worldwide in optimizing processes, ensuring quality, driving research, conserving raw materials, and serving people. They provide reliability, efficiency and flexibility for your application.