SCARA Robot Sorts Recyclables Using a Simple Conveyor Speed Feedback System

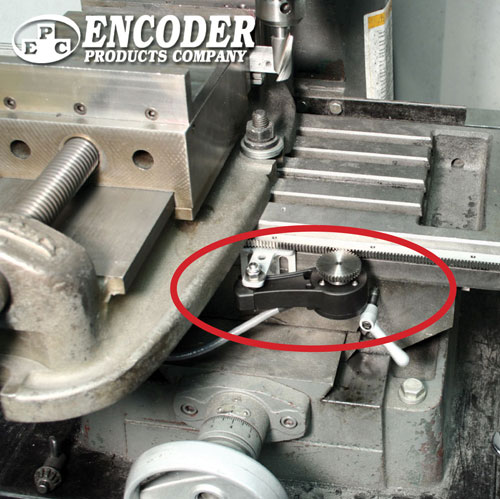

As Everest Labs was developing their system to be sold to recycling centers worldwide, they found that their robot needed speed feedback in order to track the recyclables on the conveyor, and therefore needed a simple way to install conveyor speed feedback on a gear motor.

Choosing the Right Encoder for Your Robot

Most robots use servo motors to move their joints, calling for rotary or angle encoders. As speeds increase, so do the control dynamics the motors require, sometimes making vibration mitigation just as important accuracy and resolution.

US Digital Automates Production Process Using Robot and In-House Engineering Talent

When US Digital released the E4T Miniature Optical Kit Encoder it needed to update manufacturing procedures to better handle the miniaturized encoder disks. The company decided to use automation and built the delta robot system above.

Industrial Robots: Encoders for Tool Center Point Accuracy

The use of secondary encoders on all of a robots axes, as well as the use of linear encoders for positioning the robot relative to the workpiece, enables a level of accuracy at the tool center point

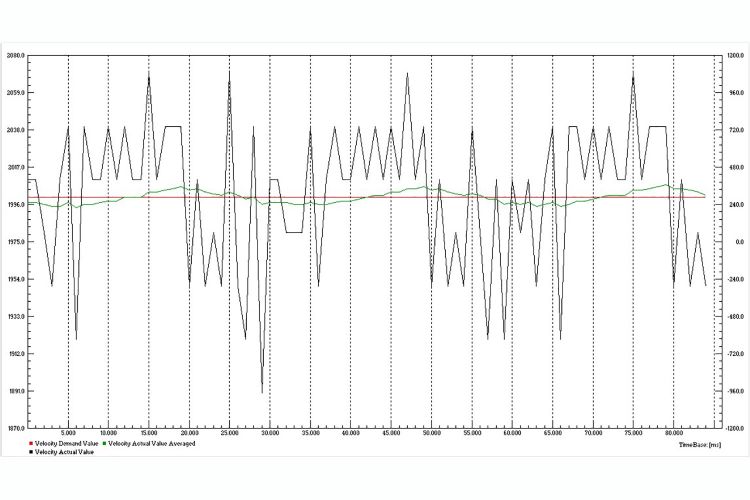

Encoder Selection: Speed Control

A general in depth analysis shows that the highest encoder resolutions are required for very precise speed control. The encoder resolution increases with the square of the demanded speed accuracy.

Tru-Trac Keeps Frankenstein Alive

This machine was assembled from various parts from other machines, so "Frankenstein" was really the only logical name for it.

What IS an Encoder?

Encoders use different types of technologies to create a signal, including: mechanical, magnetic, resistive and optical - optical being the most common.

Records 1 to 7 of 7

Featured Product

MVTec MERLIC 5.8

With MERLIC 5.8, MVTec expands its easy-to-use machine vision software. The latest version improves process reliability beyond pure image processing, offering enhanced error handling and optimized configuration. This enables faster setup and stable deployment across diverse production environments. Explore MERLIC 5.8 now

Robotics and Automation - Featured Company

KNF Neuberger, Inc.

We are KNF. Founded in 1946 in Freiburg im Breisgau, Germany, we are a family-owned manufacturer that has established itself as a global solution provider specializing in the development, design, production and distribution of diaphragm pumps for the transfer of gases and liquids or for vacuum generation. With 24 locations and over 900 employees worldwide, we continue to expand our industry expertise and broad range of applications, including medical technology, inkjet, gas analysis and laboratory.

.jpg)