Japanese Robot Manufacturer relies on Digital Twin by CENIT

CENIT and Sugino Machine Limited have agreed on a strategic partnership to further refine Sugino’s robotics and automation solutions. CENIT’s proven FASTUITE E2 software will provide the technology basis for collaboration.

Sugino Machine Limited is one of Japan’s leading providers of machine tools, industrial robots and automation solutions. Based in Namekawa City and employing about 1,200 staff, the machine maker boasts a broad portfolio covering development, production and sales of high-pressure jet cleaning equipment, drilling units and equipment for inspection and maintenance of nuclear power plants.

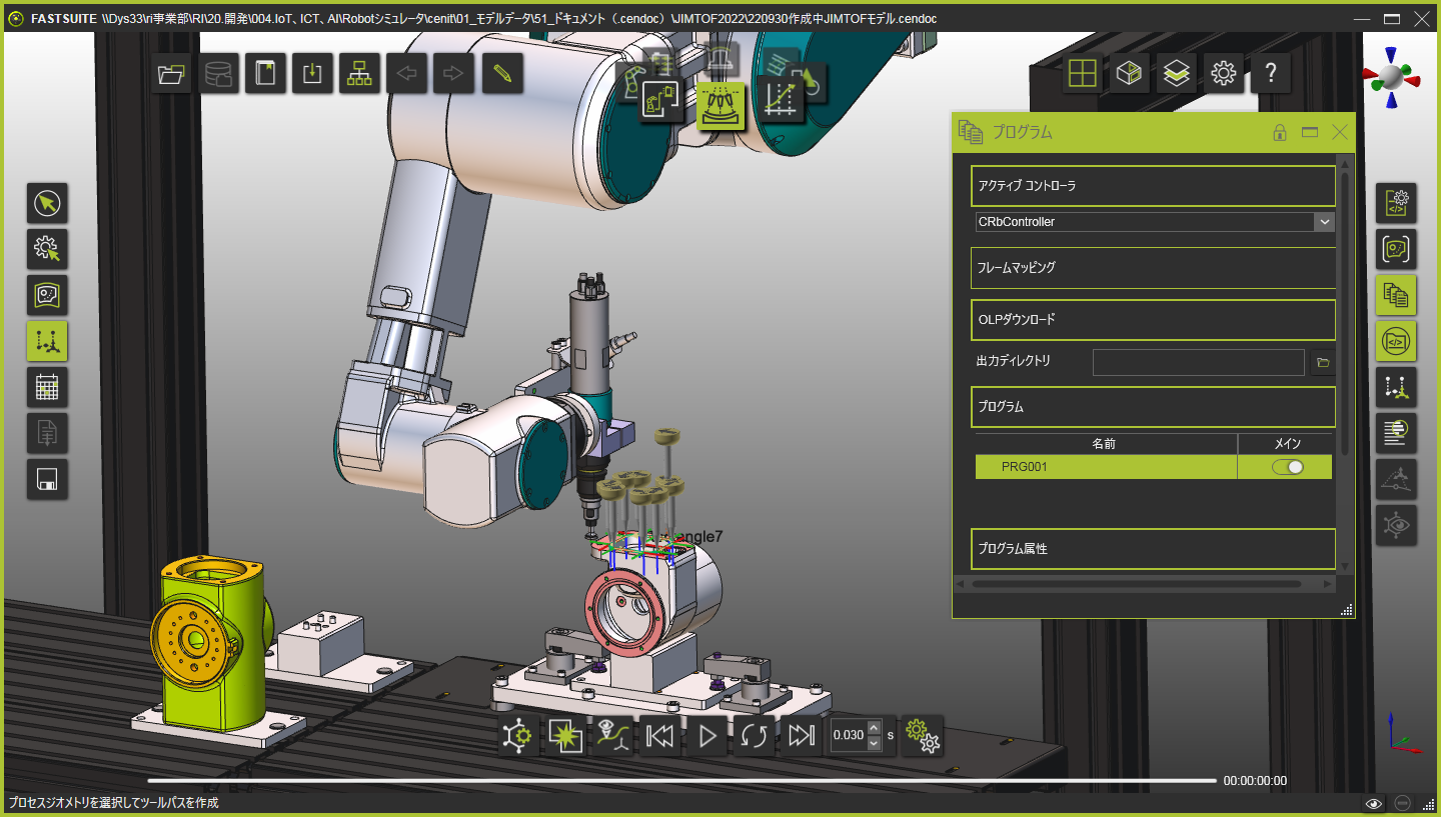

To ensure the safety, performance and efficiency of Sugino’s robotics and automation solutions, the company relies on simulation-based technology made by CENIT: FASTSUITE Edition 2 serves as a high-performance platform for SUGINO’s digital twin software, enabling offline programming, 3D simulation and PLC validation.

Img. 1: CENIT FASTSUITE Edition 2: High-performance platform for SUGINO’s digital twin software

“For a typical automation system that incorporates a multitude of machines, components, sensors and robots, you must be able to conduct test runs and final commissioning on the ground, at the client’s premises”, explains Takeo Onishi, CEO of Sugino Machine. “For us, FASTSUITE-based topics like digital twin and offline programming are a major resource for boosting quality, efficiency and profitability in our project execution”.

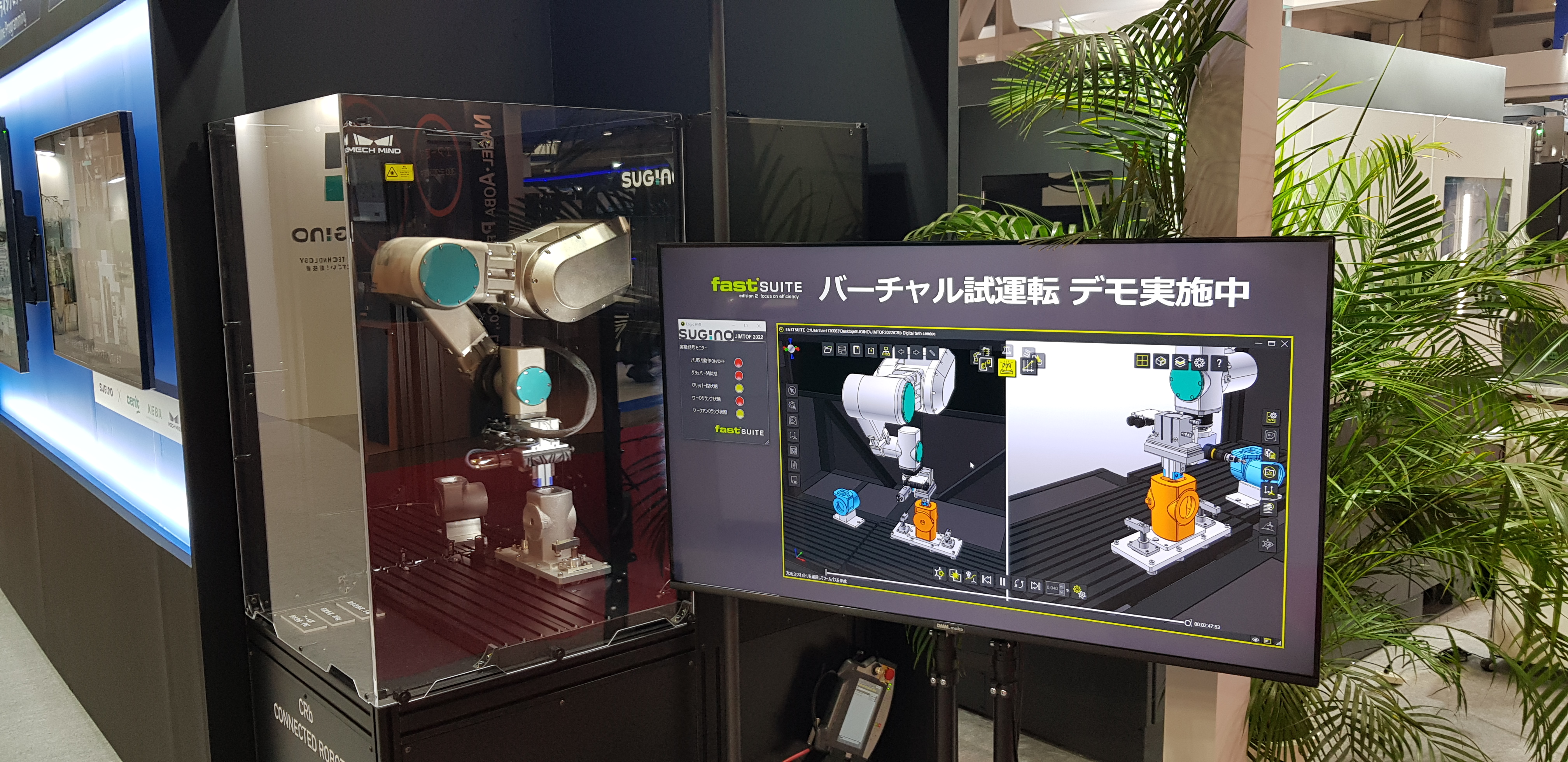

At Japan’s leading machine tool expo JIMTOF 2022 (Tokyo, November 8-13, 2022), Sugino presented its FASTSUITE E2-based “CRb” robot model and announced a closer, strategic partnership with CENIT.

Img. 2: Sugino’s new robot model “CRb” – the physical product and its digital twin in FASTSUITE

Together, CENIT and Sugino will now focus on leveraging the FASTSUITE technology for consistent and continual development of Sugino’s robotics and automation solutions – from the initial installation of automation systems to changes in plant layout to full-scale re-engineering of entire facilities.

Peter Schneck, CEO of CENIT AG, says: “We are proud to be part of SUGINO’s success as a proven technology partner in production technology and simulation solutions.” He adds: “In expanding our strategic partnerships and further refining our software competence, we strive to ensure our clients’ competitiveness and promote sustainable digitalization.”

As Gaku Sugino, Vice President of Sugino Machine, explains: “The strong performance of Sugino’s software products for robot simulation and offline programming is based on the FASTSUITE technology. We are certain that this will let us offer our clients the ideal tools for future-proof automation processes, and therefore we are pleased that CENIT will continue to collaborate closely with Sugino as a software partner.”

Img. 3: Peter Schneck (left), CEO of CENIT AG, and Gaku Sugino (right), Vice President of Sugino Machine, agree strategic partnership on robotics and automation solutions

About CENIT

CENIT empowers sustainable digitalization. With a broad solutions and services portfolio, CENIT enables clients to optimize their horizontal and vertical business processes. Our solutions are based on innovative technologies in: product lifecycle management, the digital factory, and enterprise information management. With interdisciplinary knowledge of the processes involved and their considerable expertise in the field, CENIT consultants provide customers with end-to-end advice to ensure that solutions are implemented with an understanding of the entire value chain.

With a holistic approach and based on trusted partnerships, CENIT takes responsibility for solutions on behalf of our clients. From the initial consultation to the introduction of innovative IT solutions, right through to ensuring a cost-effective operation. The CENIT team adapts to each client, taking a practical approach, which enables measurable operational optimizations. CENIT has been helping prestigious customers in key industries to gain competitive advantages for 30 years.

CENIT has round 900 employees worldwide who work with customers from: automotive, aerospace, industrial equipment, tool and mold manufacturing, financial services, and trade and consumer products industries. www.cenit.com

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product