The Collaborative Revolution: How AI, Digital Twins, and Cobots are Reshaping Manufacturing & Industry

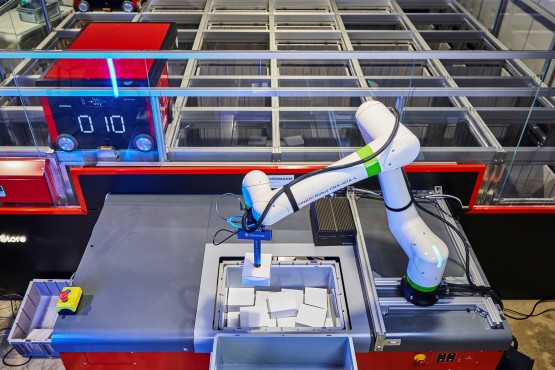

The manufacturing and logistics industries are undergoing a significant transformation due to the integration of AI, digital twins, and collaborative robots. AI acts as the intelligent core, optimizing cobot control, predictive maintenance, and supply chain management.

How to Achieve the Full Benefits of a Warehouse Digital Twin

A warehouse digital twin needs more than a highly capable WMS, it also needs a reliable technology to capture all the necessary inventory data, and this is where computer vision plays a pivotal role.

Duality AI Partners with CoVar on DARPA Program to Define Ethical Standards for Future Military Autonomous Systems

Teams will leverage digital twin simulation as part of a novel approach for benchmarking AI's ethical alignment with established ethics principles

Testing drive systems virtually - Simulink library for development and digital twin.

How will the drive actually behave in the real-life application? For brushless DC-motors from FAULHABER, this question can be answered without any hardware whatsoever.

Adoption of Digital Twins Set to Accelerate with the Latest Release of Duality's Falcon Platform Powered by Unreal Engine

Digital twin simulation is emerging as a powerful resource for solving complex problems in AI, robotics, and smart system development. It can bring understanding of the physical world to AI models

What is Digital Twin technology and why is it important for manufacturers?

Whilst uptake in smaller manufacturing firms has been slower, those within the sector are slowly starting to see the value that digital twin technology can bring, no matter the size of the business.

Climate-neutral, highly economical production through AI and digitization

Digitization and AI have become a matter of intense public discourse. However, this leads to more questions than answers. This is where automatica, held from June 27 to 30, 2023, comes in with its digital solutions and components.

How Simulation Can Secure Your Robotics Investment

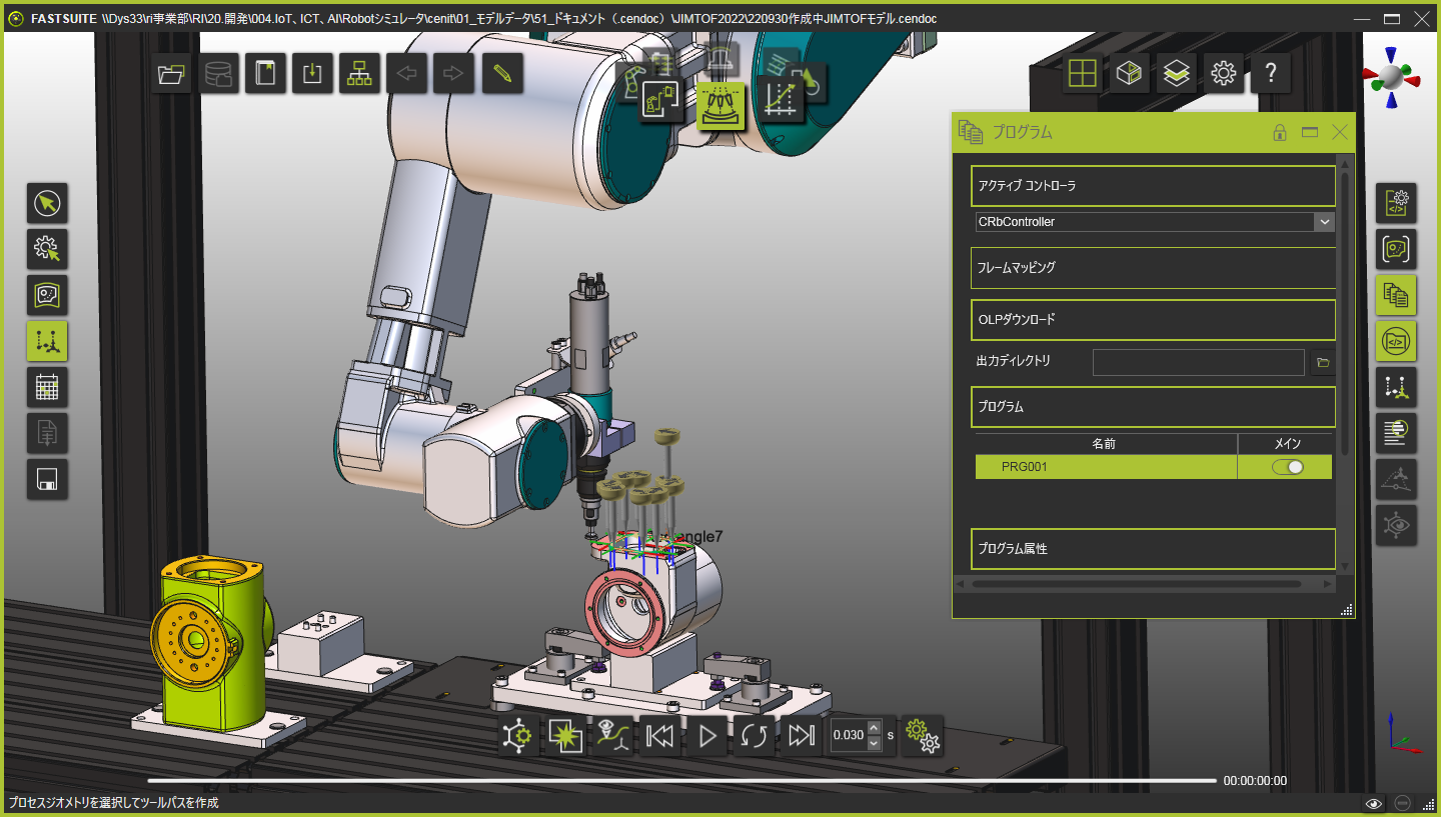

Robotics simulation can be defined as a digital tool used to engineer robotics-based automated production systems. Essentially, robot simulation employs a digital representation to enable dynamic interaction with robot models and machines in a virtual environment.

Japanese Robot Manufacturer relies on Digital Twin by CENIT

FASTSUITE E2 technology provides powerful foundation for digital twinning and offline programming at Sugino Machine

Records 1 to 9 of 9

Featured Product

ResinDek TRIGARD ESD ULTRA FOR HIGH-TRAFFIC ROBOTIC APPLICATIONS

To maximize the productivity of an autonomous mobile robot (AMR) or automatic guided vehicle (AGV) deployment, it's critical to create the optimal environment that allows the vehicles to perform at their peak. For that reason, Cornerstone Specialty Wood Products, LLC (www.resindek.com) created the TriGard ESD Ultra finish for its ResinDek engineered flooring panels. The TriGard ESD Ultra finish is ideal for high-traffic robotic applications characterized by highly repetitive movement patterns and defined travel paths.

Robotics and Automation - Featured Company

e-con Systems

e-con Systems® develops complete embedded vision solutions—including OEM cameras and edge AI compute platforms. With 20+ years of experience and expertise in embedded vision, it focuses on delivering vision and camera solutions to industries such as Robotics, Mobility, Medical and Life Science, Agriculture, Intelligent Transport Systems, Sports Analytics and more. e-con Systems' wide portfolio of products includes MIPI camera modules, GMSL cameras, USB 3.2 cameras, Depth cameras, GigE cameras, HDR cameras, low light cameras, and more. Our cameras are currently embedded in over 350+ customer products, and we have shipped over 2 million cameras to the United States, Europe, Japan, South Korea, and many other countries.