Landmark Study Reveals Wearable Robotics Significantly Boost Safety and Efficiency in Industrial Environments

The four-year study, the first of its kind, tracked ergonomics, safety, and injury metrics across more than 65 million lifts at over 40 sites in five industries: Construction, Food & Beverage, Logistics, Manufacturing, and Retail.

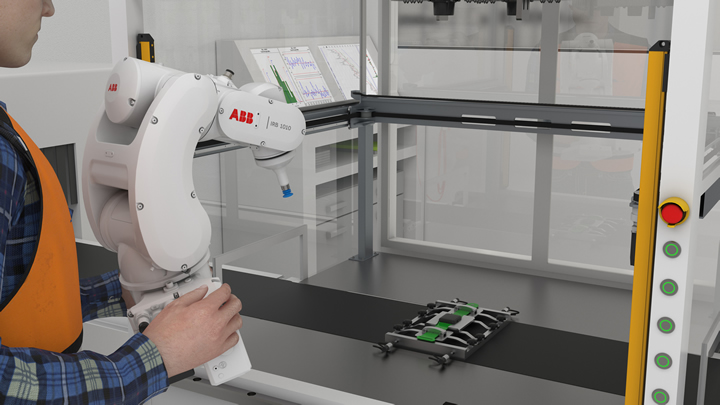

ABB unveils smallest industrial robot with class-leading payload and accuracy

Most accurate robot in class for 1.5 kg payloads for highest manufacturing quality, 50 percent higher payload than comparable robots. Consumes 20 percent less energy using OmniCore E10 controller enabling manufacturers to improve energy efficiency, reduce costs.

A Next Step in Wearable Robotics

Angel Robotics is a Korean startup company that focuses on wearable robots for rehabilitation, Their Exoskeleton is competition proven.

Wearable Device Preserving the Operators' Health During Assembly Operations

Comau's MATE exoskeleton was chosen by IVECO to reduce the fatigue on the upper limbs suffered by the operators engaged in the heaviest activities inside the various production departments of the company.

Exoskeletons and Exo-suits: Exploring the Scope of Wearable Robots

However, studies in the field of wearable robots are opening up innumerable possibilities of telepresence and telemanipulation that could change the degree and nature of functionality and productivity in humans.

Wandelbots wants to reinvent the way we program robots

Darrell Etherington for TechCrunch: Its first product is a sensor-laden suit that a person can wear to demonstrate actions so that a robot can then replicate what they do.

ASU's Tom Sugar explores the next step in wearable robotics

ASU Now: Engineering professor to host, present at WearRAcon17 robotics conference in Phoenix.

Records 1 to 7 of 7

Featured Product

NVIDIA RTX PRO BLACKWELL DESKTOP GPUs

NVIDIA RTX PRO - Built for Professionals - NVIDIA RTX PRO Blackwell Desktop GPUs feature the latest breakthroughs in AI, ray tracing, and neural rendering technology to power the most innovative workflows in design, engineering, and beyond.

Robotics and Automation - Featured Company

CMES Robotics Inc.

Powered by AI, CMES Robotics enables 3D vision for factory robots. CMES AI vision software enables robots to recognize unstructured, flexible, or deformed objects, pick them up, and loading and unloading. CMES Vision software has been deployed worldwide for random palletization and depalletization along with void filling applications. CMES Robotics automates your warehouse, logistics, and supply chain.