Discussing West Pack with Dorner Conveyors

Conveyors, although often a last thought, can play a pivotal role in the optimization of a manufacturing facility. A processing line can only go as fast as the slowest piece of equipment.

Booth #5014

Everything You Want to Know About Alpine Conveyors

The Alpine Conveyor is a compact spiral configuration commonly used as an accumulation or elevating buffer zone between machines or as a process step for cooling or drying. It can also be used for line balancing or product changeover purposes.

Everything You Want to Know About Wedge Conveyors

Wedge Conveyors are used to take products from production floor level to a higher level or vice versa. Products are wedged between opposing conveyors aligned vertically or horizontally and are moved swiftly but securely.

Can You Complete Your Project Without A Conveyor? The Pros and Cons

Lets explore some common misconceptions about conveyors, as well as some pros and cons of conveyor alternatives.

Trends in Conveyor Systems and Technology

Conveyors today are built to your specifications to improve efficiency and output of your production line. Theres no reason to settle for a conveyor thats being shoe-horned into your application

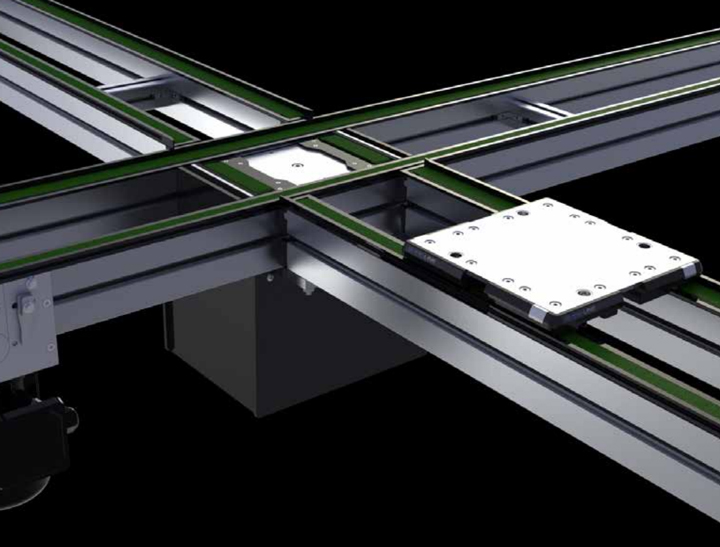

Glide-Line Conveyor Case Study: Automating in-context Conveyor Configuration With Solidworks

We needed a powerful configuration platform so customers would have access to complete assemblies, could easily put systems together using automated snaps, and manage operational states

Farason Corporation Chooses Dorner Conveyors to Integrate with its Robotic Machine to Successfully Assemble Coin Proof Sets

Placing coins into a coin presentation case insert sounds like an easy thing to do, right? But when the application calls for placing several thousand coins in exact places on moving inserts every day, the task becomes much more demanding.

Records 16 to 22 of 22

Featured Product

Midwest Motion Products is a leading provider of robust and reliable Motion Control Products.

MMP specializes in supplying high-quality Brushed & Brushless DC Motors & Gearmotors for Robotics and Automation Equipment with a wide range of motor windings and gear ratios. With an impressive track record of more than 8,000 released DC Gearmotors designs and over 2,000,000 individual part numbers, we are renowned for our ability to handle large-scale orders. Due to our huge on-hand inventory, we are also well known for lightning-fast delivery of our standard products. We take pride in our dedicated customer service and our team of knowledgeable sales and engineering experts who are ready to assist you with custom design solutions tailored to your specific application. Additionally, we also offer a wide range of complimentary products, such as DC Motor Controls, DC Linear Actuators, AC-DC power Supplies, and DC Servo Amplifiers and others.